-

Spirally Wound Coils Strap-Copper Coils

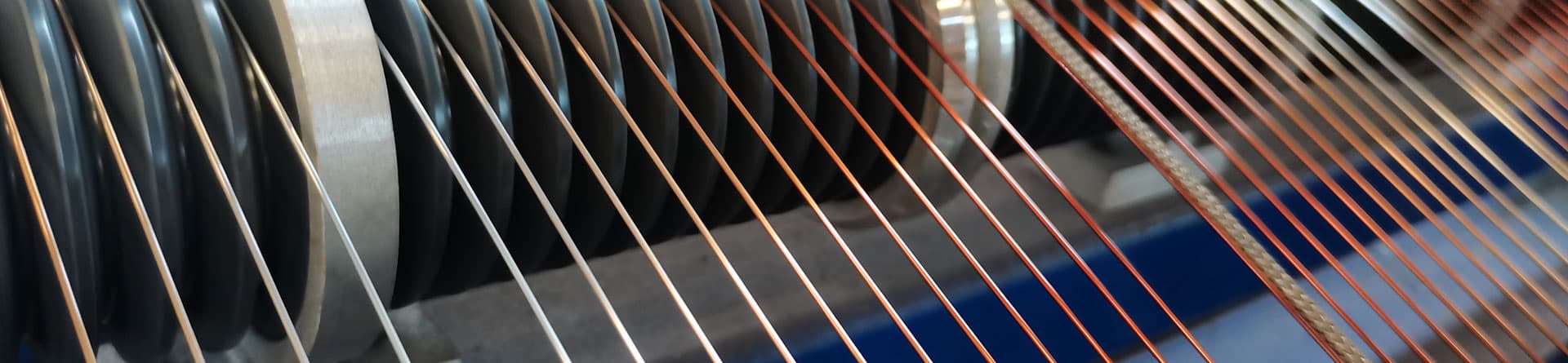

Strap-copper coils with paper or other insulating material between turns merely require a strongtension and some hammering with a rawhide mallet or a piece of wood interposed between the coil and the hammer in order to cause the insulated strap or ribon of copper to lie properly in place.

-

Solenoids

Solenoids

Solenoids generally applies to all coils used in controllers and general forms of electromagnets wherein an iron or steel core is to be placed after assembly to form an electromagnet of either the movable-core or the stationary-core type.

-

Transformer for Microwave Oven

Transformer for Microwave Oven

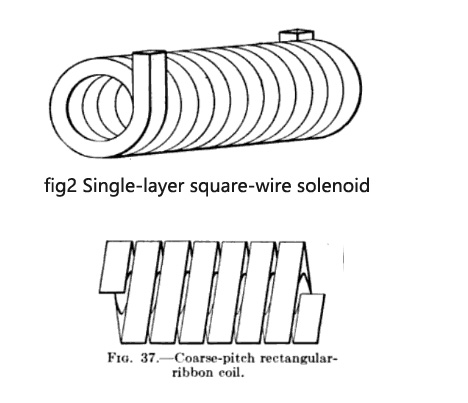

Microwave oven transformer is a kind of magnetic leakage transformer. From its structure, it can be seen that its primary and secondary coils (primary 220V, secondary 1500V-2100V, filament voltage 2.6V~3.3V) are wound separately, with a certain distance between them, and a component of magnetic silicon steel sheet. This structure makes its volt-ampere characteristics and ordinary power supply transformer is very different, when the load current increases, its output voltage will drop significantly, close to constant current characteristics. In addition, when the power supply voltage fluctuations, there is a certain voltage regulating effect, which is similar to the transformer in the welding machine, both of which need coils with lacquered wire (magnetic wire) to complete the work.

-

Copper Strip Windings

Copper Strip Windings

Copper Strip Windings are composed of lacquered copper wires, which are the basic components of the circuit of every motor or equipment.

-

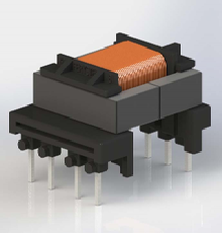

Ferrite Transformer

Ferrite Transformer

The core materials in ferrite core transformers are non-conductive ceramic compounds that are ferromagnetic in nature. When the windings of transformers are made of ferrite, they are called ferrite type transformers. The ferrite cores in transformers are made of iron oxide and are combined with zinc, nickel and manganese compounds. These compounds have very low coercivity and are known as soft ferrites. Ferrites have several advantages over other core transformers due to their mechanical and electrical properties. These include high current resistivity, as well as low eddy current losses and high permeability over a wide range of frequencies. All these characteristics make ferrite transformers ideal for a variety of high-frequency transformers, tunable inductors, wideband transformers, and high-frequency circuits from 10 KHz to 50 MHz.

-

Current Transformer

Current Transformer

A current transformer (CT) is a type of transformer used to measure alternating current. It produces an alternating current (AC) in the secondary, which is directly proportional to the AC in the primary. A current transformer, together with a voltage or potential transformer, is a transformer. Current transformers are designed to provide a reduced copy of the current in the high voltage line and to isolate measuring instruments, meters, relays, etc. from the high voltage power supply circuit. Unable to sense or pass through the large AC current of ordinary ammeters, and the current coil of a wattmeter, the wattmeter can be easily measured by using current transformers and ordinary low-range instruments.

-

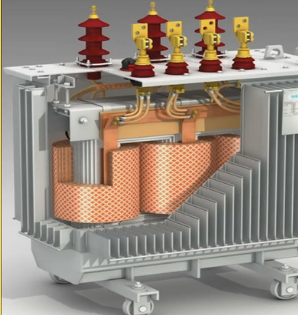

Oil – Immersed Transformer

Oil – Immersed Transformer

Oil - immersed transformer is a kind of voltage conversion device which uses oil - cooled way to reduce transformer temperature. Unlike dry transformers, the body of oil-immersed transformers is mounted in a welded steel tank filled with insulating oil. When the oil-immersed transformer is in operation, the heat of the coil and core is first converted into insulating oil, and then into the cooling medium. And according to the capacity size, it can be divided into immersed natural cooling transformer and immersed forced air cooling transformer.

-

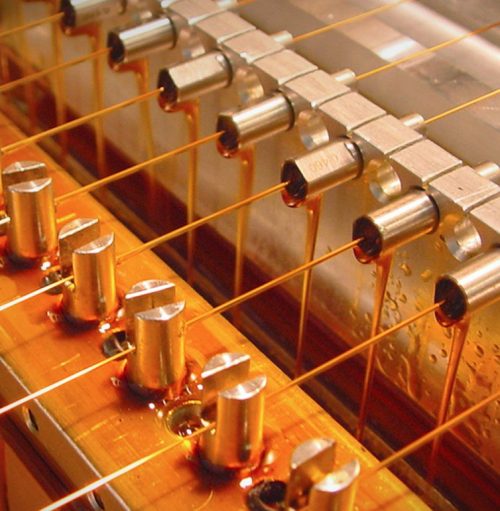

Enamelling Machine

Enamelling Machine

The enamelling machine is a machine that coats the surface of metal wire with insulating paint and makes it solidify. It is an important equipment for the production of enameled wire in the electromagnetic industry. Its function is to evenly wrap a layer of insulating paint outside the processed copper wire or aluminum wire. There are a lot of diluents and organic solvents used in the production of enameled wire, mainly including benzene, xylene and cresol, which volatilize when the film is heated and cured, causing environmental pollution and energy waste. There are more and more manufacturers of enameled wire. The energy-saving and environmental protection of the enameled wire maker has become a problem that can not be ignored.

-

Wind Turbine

Wind Turbine

A wind turbine is a turbine powered by wind energy. An aerospace research institute in Wilbrahan, Massachusetts, has developed a wind turbine that can generate electricity at half the cost of a conventional turbine. Wind turbines. The new design produces as much power as conventional wind turbines, but with blades half the diameter. Smaller blade sizes and other factors allow the new turbines to be clustered closer together than traditional turbines, increasing the amount of electricity produced per acre.

-

CEEG Electric Company

CEEG Electric Company

CEEG Electric Company is headquartered in Nanjing, formerly known as JiangSu Zhongelectric Equipment Manufacturing Company, which was established in 1990. it was restructed and established in 2003. CEEG Electric has four major industries so far, namely power transformer, solar photovoltaic, insulation and protection materials, complete electrical sets, and 15 holding and wholly-owned subsidiaries. In addition, Yangzhong has built a global dry transformer production base, a domestic solar photovoltaic industry base in Nanjing, and a domestic new energy technology industry base in Shanghai. CEEG Electric became a Zhenjiang company listed in the United States On May 18, 2007 .

-

Schneider Electric Company

Schneider Electric Company

Schneider Electric Company started in France in 1920. In 1836, the Schneider brothers took over the Creusot foundry, which was in trouble at that time. Two years later, they established Schneider & Cie. In 1891, Schneider began to enter the emerging electricity market, and reformed itself. 1981-1997 Schneider Electric set aside some non-strategic activities and continued to focus on the power industry to this day.