Description

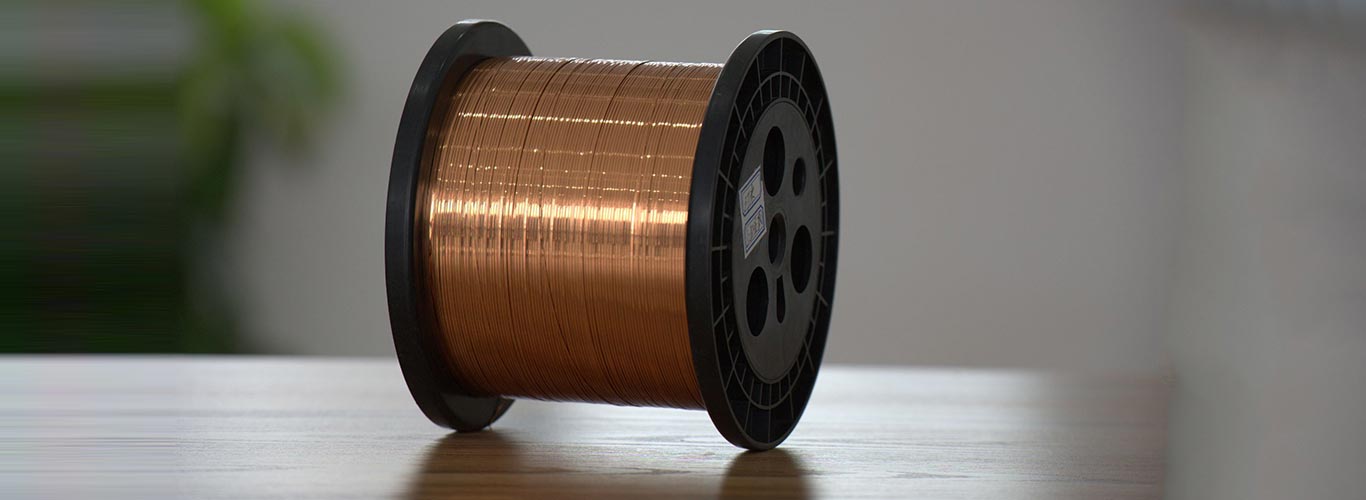

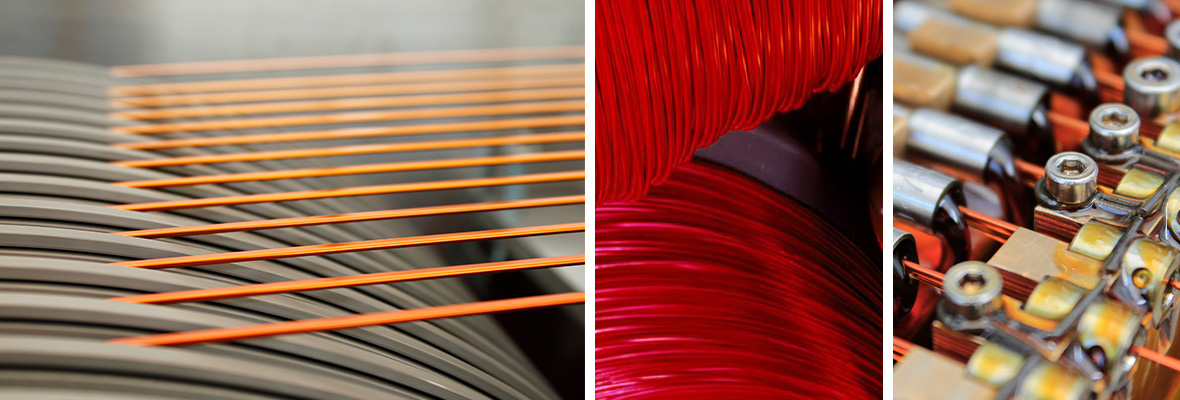

Enameled copper wire is the main type of winding wire. It consists of a conductor and an insulating layer. Copper’s high electrical conductivity makes it a perfect metal for electrical applications, and it can be fully annealed and electrolytically refined in order to wind electromagnetic coils more tightly. By coating the wire with an insulating layer (usually one to four polymer films), the wire is protected from current contact with itself and other wires, preventing short circuits and extending the working life, efficiency and application of the wire. After annealing to soften, the bare wire is painted and baked many times. However, it is not easy to produce products that meet the requirements of both standards and customers. Affected by raw material quality, process parameters, production equipment, environment and other factors. As a result, various enameled wires have different mass characteristics, but they all have mechanical, chemical, electrical and thermal properties.

Raw material: anaerobic copper rod

Product number: No.26 to 50

Insulation materials: cotton yarn (below 100 degrees), impregnated kraft paper (around 105 degrees), organic enamel, synthetic organic enamel (120-155 degrees), mica, glass fiber (180 degrees), polyester enamel, polyvinylformal enamel, polyester imide enamel (200 degrees).

Thermal rating: 180°C, 200°C, 220°C, 240°C

Dimensions: Diameter 0.025 to 0.4/ 0.45 to 7.35 /0.51 to 7.62 mm; 1 – 25 SWG,

Heat resistance rating :120 (Class E); 180 (Class H); 200 (Class C); 220 (Class C+); 240 (HC Class)

Heat resistant thickness :G1,G2,G3 and G4

Certification system: UL, ISO9001, ISO14001

Enameled wire is the main conductor for electrical energy conversion and use, including transformers, inductors, motors, generators, loudspeakers, hard disk actuators, electromagnets and other electrical equipment requiring winding coils. Especially in recent years, the electric power industry has achieved sustained and rapid growth, and the rapid development of household appliances has brought a broader field for the application of enameled wire. Therefore, higher requirements are put forward for enameled wire. In the generator sector, manufacturers are increasingly turning to equipment that runs at higher temperatures and electrical conductivity, and enamelled copper wires from ZhengZhou LP Industry are the ideal solution.

Product Datasheet