Enameled Round Copper Wire

Enameled Round Copper Wire is a very hot product, make of copper conductor and enamel materials, which is a principal component of transformers, inductors, motors, and other electrical devices. All electrical products in life are inseparable from it.

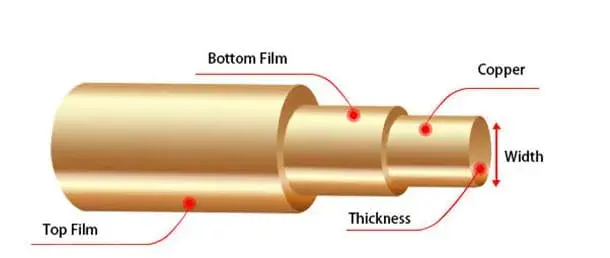

Enameled Round Copper Wire structure

Enameled Round Copper Wire main technical parameters

| Name | Enameled Round Copper Wire |

| Conductor | Copper |

| Dimension | Thickness(a):0.016-7mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC) |

| Insulation Thickness: | G1,G2 or single build, heavy build |

| Standard | IEC 60317-16,60317-16/28,MW36 60317-29 BS6811, MW18 60317-18 ,MW20 60317-47 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

The insulation materials and application

| Heat class | Range of diameters mm/section mm | Type of insulation | Thermoplasticity | Heat shock | Properties and applications |

| 120(E) | 0.100-5.000 | polyester | 150℃ | 140℃ | oil-immersed transformer |

| 155(F) | 0.100- 5.000 | Polyesterimide | 270℃ | 175℃ | Designed for manufacturing of the windings in electric machines. apparatus and devices, all kinds of magnet coil |

| 180(H) | 0.100- 5.000 | Polyesterimide | 300℃ | 200℃ | |

| 200(C) | 0.100- 5.000 | Polyesterimide +Polyamidimide | 330℃ | 220℃ | |

| 180(H) | 0.100- 5.000 | Polyesterimide +Polyamidimide | 300℃ | 200℃ | Intended for application in the devices working with refrigerants in mixture with coolant oils |

| 200(C) | 0.250- 1.080 | Polyesterimide +Polyamidimide +Polyamide | 320℃ | 220℃ | With self-bonding layer |

| 155(F) | 0.100- 5.000 | Polyurethane | 200℃ | 175℃ | Designed for winding of the transformers. |

| 180(H) | 0.100- 5.000 | Polyurethane | 230℃ | 200℃ | |

| 200(C+) | 0.500- 2.500 | Polyurethane | 240℃ | 220℃ | magnet coils of aviation, military and marine application |

| 240(HC) | 0.500- 2.500 | Polyurethane | 270℃ | 260℃ |

Advantages

Very good mechanical resistance

Directly solderable

Very short soldertime

Excellent mechanical resistance

Very good hairline crack avoidance

Solderable at 470 °C

High heat resistance

Very good resistance to transformer oils

Very good resistance to typical solvent

Freon resistant

Excellent resistance to mechanical stress

Handling and Usage Tips:

Careful Winding: When winding the wire into coils, it’s essential to do so carefully to avoid damaging the enamel coating, which could lead to short circuits.

Proper Storage: Store the wire in a dry environment to prevent the insulation from absorbing moisture, which could degrade its performance.

Soldering: The enamel needs to be stripped off at the ends before soldering to ensure a good electrical connection.

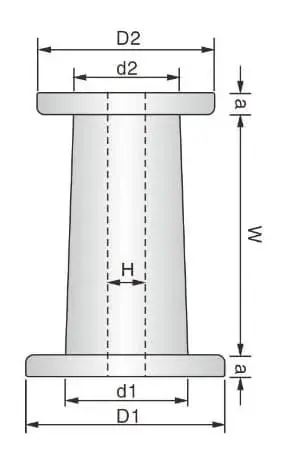

Packing – plastic reel size

| Types | Outer diameter(mm) | Inner diameter(mm) | Hole diameter(mm) | width | thickness | Wire weight(kg) | Range of round wire diameter(mm) | ||

| D1 | D2 | d1 | d2 | H | M | a | |||

| PT4 | 140 | 124 | 86 | 74 | 26 | 170 | 15 | 4.0 | 0.04-0.13 |

| PT10 | 180 | 160 | 110 | 96 | 30 | 200 | 15 | 10 | 0.10-0.19 |

| PT15 | 200 | 180 | 110 | 96 | 30 | 200 | 15 | 15 | 0.18-4.50 |

| PT25 | 230 | 215 | 130 | 115 | 30 | 250 | 15 | 25 | 0.18-5.00 |

| PT60 | 300 | 270 | 175 | 150 | 45 | 350 | 25 | 60 | 0.18-5.00 |

| PT100 | 315 | 300 | 200 | 180 | 100 | 425 | 38 | 100 | 1.50-7.00 |

| PT200 | 400 | 375 | 250 | 225 | 100 | 530 | 50 | 200 | 1.45-7.00 |