Solenoids design

Solenoids generally applies to all coils used in controllers and general forms of electromagnets wherein an iron or steel core is to be placed after assembly to form an electromagnet of either the movable-core or the stationary-core type.

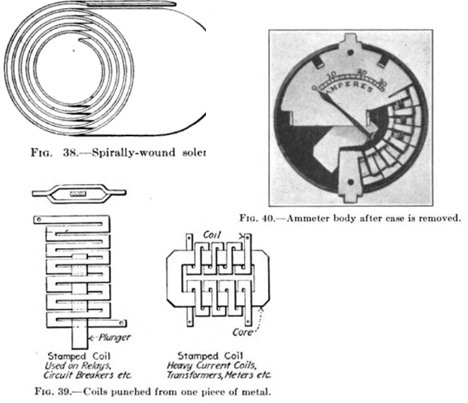

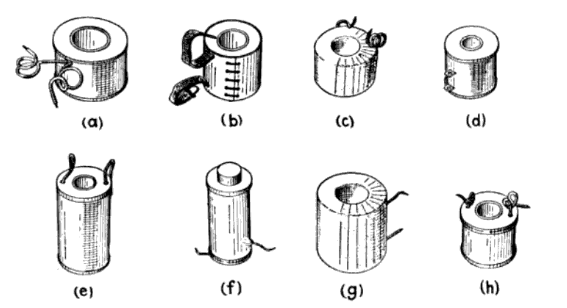

The unmounted solenoids may be mounted in any of the conventional forms in Fig.1 which have various types and positions of leads and terminals, and different kinds of end washers and covers, coils c and g being taped.

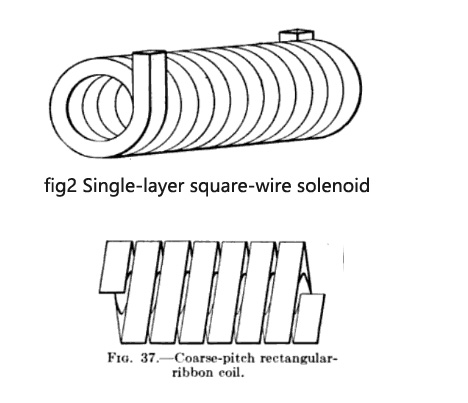

Figures 2 and 37, respectively, illustrate a single-layer solenoid consisting of square wire, and & coarse-pitch rectangular-ribbon coil, as used on overcurrent relays. The spirally wound solenoid in Fig. 38 consists of strap or ribbon copper, and is used principally in field coils and lifting magnets, also being suitable for large transformers. This latter solenoid is the nearest approach to the ideal coil so far as the pitch of the turns is concerned, and heat is readily conducted through the coil wall when the insulation is thin.

A coil or solenoid formed by stamping or punching out sheet metal strips, which are alternately bent upward and downward, is covered by U. S. Patent No. 1184536, issued to M. B. Kassel and A. Finkenberg. It is especially intended for use where strong currents fow,as in overcurrent relays, and is a series or current coil. Since it does not require any insulation in addition to the surrounding air or soldering of terminals, it can withstand high temperatures. Being of rigid construction, part of the stamping which forms the coil can be used for mounting insulating blocks containing contacts and supports for the plunger. Two applications are shown in Fig. 39. The application of the principle to a pocket ammeter is illustrated in Fig. 40.