Enameled Copper Clad Aluminum Wire

ECCA – Conductor

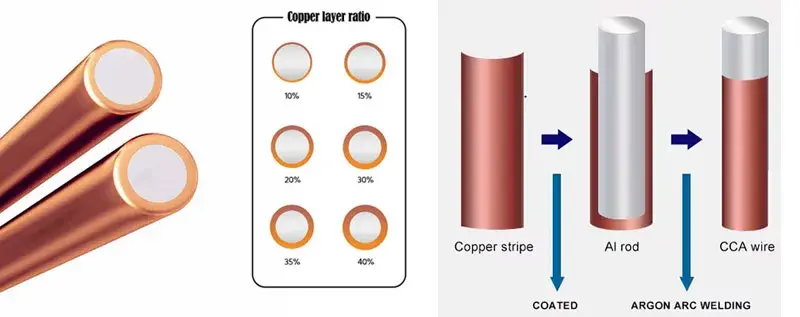

Copper Clad Aluminum (CCA) is a clad bi-metal utilizing electrical conductor grade aluminum as its core and oxygen free copper for its outer layer. The cladding process creates a permanent continuous weld between the two metals. The composite wire is uniquely suited to electrical applications where weight and conductivity issues are critical. The copper makes up either 10% or 15% of the cross sectional area of the wire and assures excellent solderability. AC conductivity at frequencies greater than 5MHz is equal to solid copper. CCA is manufactured in accordance with the requirements of ASTM B-566. Film Insulations are available on CCA. See the magnet wire insulation guide for enamel options.

Main specifications

| Name | ECCAW | |

| Conductor | Copper clad aluminum | |

| Dimension | Round | 0.19-4.0 mm |

| Insulation Thickness | Single, heavy or according to your requirement | |

| Standard | IEC, NEMA, GB, JIS | |

| Paking | 30kg~150kg Poly-wood spool (250*500/ 250*600) | |

Thermal class and insulation materials

| Enameled Type | Polyester or Solderable Polyurethane | Modified Polyester or Solderable Polyurethane | polyester-imide Or Solderable Polyurethane | Polyamide-imide | polyester-imide /Polyamide-imide |

| Products type | PEW/130 UEW/130 | PEW/155 UEW/155 | EIW/180 UEW/180 | EIW/AIW/200 | EIW(EI/AIW)/220 |

| Temp Class | 130 | 155 | 180 | 200 | 220 |

| Insulation Grade | Grade1/Grade2/ Grade3 | Grade1/Grade2/ Grade3 | Grade1/Grade2/ Grade3 | Grade1/Grade2/ Grade3 | Grade1/Grade2/ Grade3 |

| Standard | IEC,NEMA,JIS,GB or according to customers’ requirements | ||||

Structure and Composition

Core:

Aluminum: The core of the wire is made from aluminum, which is lighter and less expensive than copper.

Cladding:

Copper Cladding: A thin layer of copper is clad around the aluminum core. This copper layer is typically applied through electroplating or metallurgical bonding processes.

Insulation:

Enamel Coating: The wire is coated with an insulating layer of enamel. This enamel provides electrical insulation, protecting the wire from short circuits and environmental factors like moisture and chemicals.

Applications of Copper Clad Aluminum

Music

Amplification, Noise elimination, custom guitar cables, loudspeakers, subwoofers and high performance audio

Power

Wireless chargers, custom power supplies

Aerospace, military, commercial

Extreme temperature sensors, noise control, custom magnetics, underwater sensors

Space propulsion systems, sensors

Booms (Retractable tube for inflight tranfer of fuel)

Specialty resistors and capacitors

Wireless power transfer systems using inductive coupling through magnetic field

Electromagnetic radiation and atomic research

Coaxial Cable

Microwave connectors and cables

CATV semi-rigid trunk, distribution cables

Hobby motors and wiring

Residential power conductors

Automotive

Advanced fuel injection systems

Technical equipment

Outdoor control panels, sensors, printers

Hearing Aids

Button Cell Batteries

Properties

The properties of copper-clad aluminium wire include:

Less expensive than a pure copper wire

Lighter than pure copper

Higher electrical conductivity than pure aluminium

Higher strength than aluminium

Electrical connections are typically more reliable than pure aluminium[citation needed]

Typically produced as a 10% or 15% by copper volume product