How to produce the CTC?

Materials and Preparation

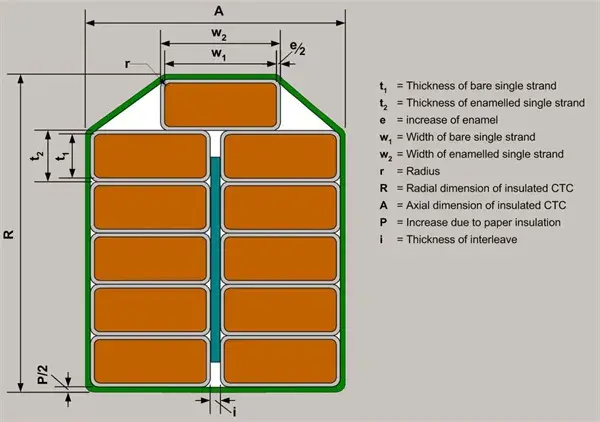

- Selection of Conductor Material:

- Copper or aluminum strips are typically used for CTC due to their excellent electrical conductivity.

- The strips are usually rectangular in cross-section to maximize packing density and minimize losses.

- Insulation:

- Each individual strand is coated with an insulating layer, usually a thin film of enamel or another insulating material.

Manufacturing Process

- Strand Preparation:

- The conductor strips are cut to the desired length and dimensions.

- The strips are then coated with the insulating material if they are not pre-insulated.

- Stranding and Stacking:

- The insulated strands are arranged in a specific pattern and stacked to form a bundle.

- The arrangement ensures that each strand is in the correct position for subsequent transposition.

- Transposition:

- The strands are continuously transposed along the length of the cable. This involves twisting and swapping the positions of the strands in a precise and regular pattern.

- This transposition ensures that each strand experiences similar electrical and magnetic environments, reducing losses due to eddy currents and circulating currents.

- Binding and Wrapping:

- The transposed bundle of strands is bound together using a suitable binding material.

- An additional layer of insulation is often applied to the entire bundle to provide mechanical protection and electrical isolation from other components.

- Forming and Shaping:

- The CTC is shaped into the desired form, which could be a rectangular or oval cross-section, depending on the application.

- This shaping process ensures that the CTC fits properly into the transformer or reactor windings.

Quality Control and Testing

- Electrical Testing:

- The completed CTC is subjected to various electrical tests to ensure it meets the required conductivity and insulation specifications.

- Tests include measuring resistance, insulation integrity, and checking for continuity.

- Mechanical Testing:

- Mechanical properties such as flexibility, tensile strength, and resistance to mechanical stresses are tested.

- Ensuring that the CTC can withstand the mechanical demands of the application is crucial.

- Thermal Testing:

- Thermal performance is evaluated to ensure the CTC can operate within the desired temperature range without degradation.

Final Assembly and Packaging

- Final Inspection:

- A thorough inspection is conducted to check for any manufacturing defects or inconsistencies.

- This includes visual inspections and verification of all test results.

- Packaging:

- The finished CTC is carefully packaged to prevent damage during transportation.

- Appropriate labeling is applied to ensure traceability and proper handling instructions.