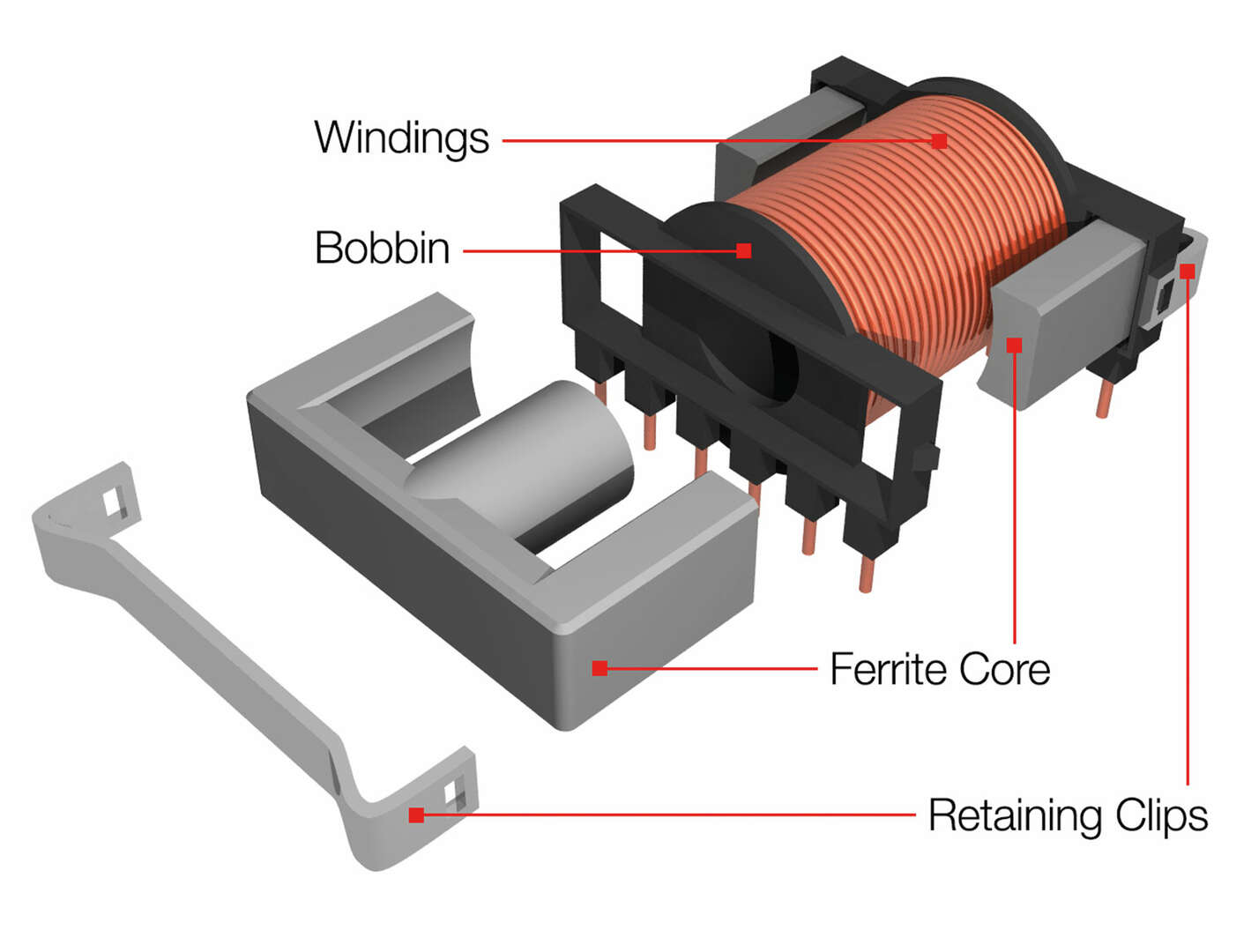

What is a Ferrite Transformer?

The core materials in ferrite transformers are non-conductive ceramic compounds that are ferromagnetic in nature. When the windings of transformers are made of ferrite, they are called ferrite type transformers. The ferrite cores in transformers are made of iron oxide and are combined with zinc, nickel and manganese compounds. These compounds have very low coercivity and are known as soft ferrites. Ferrites have several advantages over other core transformers due to their mechanical and electrical properties. These include high current resistivity, as well as low eddy current losses and high permeability over a wide range of frequencies. All these characteristics make ferrite transformers ideal for a variety of high-frequency transformers, tunable inductors, wideband transformers, and high-frequency circuits from 10 KHz to 50 MHz.

The characteristics of Ferrite Transformer

Ferrite cores for transformers are basically divided into two types: manganese zinc ferrite (MnZn) : the chemical formula is (Mn a Zn (1-a) Fe2O4). These cores have higher saturation levels and higher permeability than NiZn. MnZn cores are ideal for applications operating at frequencies below 5MHz. The impedance of these cores makes them ideal for inductors up to 70 MHz. Nickel-zinc ferrite (NiZn) : Chemical formula is NiaZn (1-a) Fe2O4. These cores have higher resistivity than MnZn and are used in frequency applications ranging from 2MHz to hundreds of MHz. NiZn is considered ideal for inductors above 70 MHz. These cores are temperature sensitive and have low Curie temperatures (below 500oC).

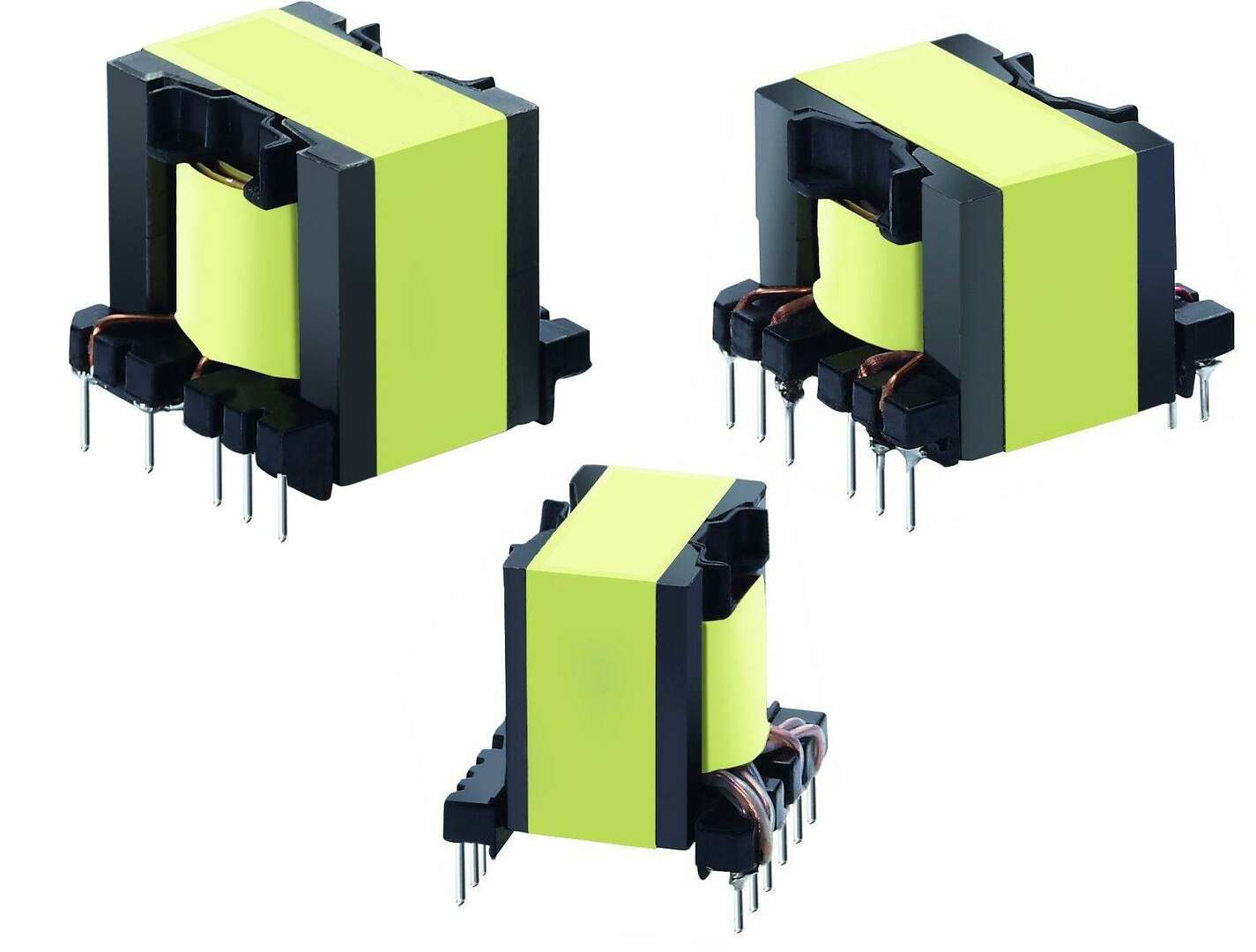

The Workplace of Ferrite Transformer

Ferrite cores for transformers are classified according to the following shapes: E, I cores: These cores are characterized by simple spool winding and ease of assembly. E, I cores are used in power, differential and telecommunications inductors, as well as broadband, converter and inverter transformers. ETD cores: These cores have a central column with minimal winding resistance. The size of these ETD cores can be optimized for power transformer efficiency. These cores are ideal for power transformers and inductors. EFD core: With its cross-sectional area, EFD cores are ideal for compact transformers as well as a variety of inductor and transformer applications. EER core: The magnetic core has a circular central column, which can shorten the winding path length compared with the square central column. A variety of structures can be used in different working environments.