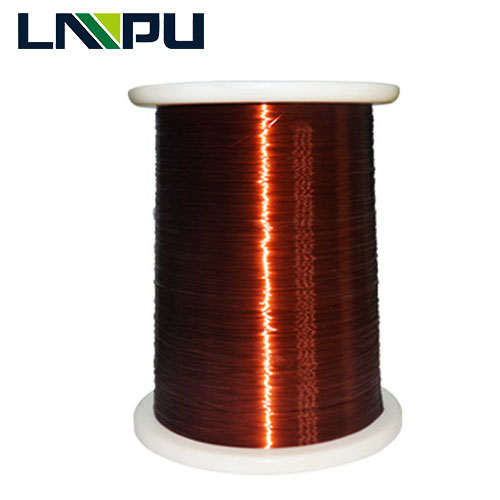

Description

Rewinding lacquered copper wire is an essential material for motor and transformer windings. Copper wires are available in different sizes (size 32 to 18). The specifications of the rewinding copper wire depend on the windings required for the particular motor or transformer. Wires with diameter of 0.500 to 4.000 mm are suitable for submersible motor windings. Enameled copper wire has a large market among motor and transformer manufacturers, and this rewinding wire is also used for the winding of motors and transformers. The reason for its widespread use is that copper is resistant to atmospheric corrosion because a uniform oxide layer is formed on the surface of the metal.

There are two types of enamel ovens. The first involves running a wire through an oven and heating it directly to the desired temperature using a heater. The second is the wire running through a stainless steel tube (like an annealed tube) that is heated through a heater to the desired temperature, known as indirect heating. Enameled wire is 0.40 mm in size. Copper/lacquered copper wire has a large market among motor and transformer manufacturers, and this type of wire is also used for motor and transformer rewinding. The reason for its widespread use is that copper is resistant to atmospheric corrosion because a uniform oxide layer is formed on the surface of the metal. In addition, copper conductor also has good mechanical properties, namely good mechanical ductility and formability. It can be easily welded or welded. The melting temperature of copper is 1083 degrees.

Copper is the most commonly used conductive metal. Lacquered copper wire has a good market in the motor and transformer industry for winding and rewinding of motors and transformers. Wire is made by cold drawing hot rolled wire/bar on more molds to reduce its size and increase its physical properties. In continuous drawing, the wire is fed through several dies and a series of pullers. Enameled copper wire is used for all types of electric motors. It is used to make automotive electrical parts, such as car combustion and so on. It is estimated that more than 40% of the total rewinding wire production in lacquered copper wire is used in the motor and transformer industry for winding and rewinding. Transmission lines are another important area, and copper lines are heavily used along with rival metals such as aluminum and steel.

Product Datasheet