-

2023-01-16

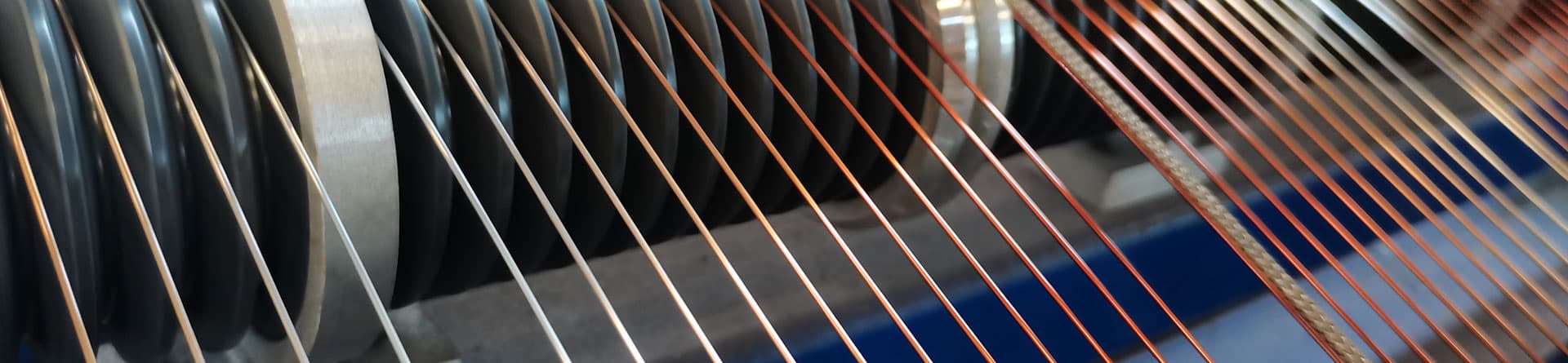

Magnet wire, or enameled wire, is a copper or aluminum wire covered with a very thin layer of insulation.

-

2023-01-14

Q: What's the difference between an enameled aluminum wire and an enameled copper wire?

-

2023-01-10

Winding or coil - a length of wire or conductor wound in a specific shape, in order to achieve specific magnetic, electric or electromagnetic properties of such configuration.

-

2023-01-09

Enamelled wire is a metallic conductor insulated with a varnish and generally used for electrical applications.

-

2023-01-06

Enamelled wire with is widely used in windings of small and medium size electric motors and transformers, as well as other electromagnetic devices such as sensors and actuators.

-

2023-01-05

For definitions, general notes on methods of test and the complete series of methods of test for winding wires, see IEC 60851-1.

-

2022-12-29

Painting is the process of applying enameled wire enamel to a metal conductor to form a uniform paint layer with a certain thickness.

-

2022-12-27

Solderable insulation is a special film insulation that is used on magnet wire in low cost, high volume applications.The magnet wire, with this solderable insulation,is wrapped around the terminal or pin.

-

2022-12-26

The major application areas are electrical and electronics, automotive, medical and aerospace.

-

2022-12-26

In rare cases pin holes develop at wire enamaltion as film thickness decreases. At PVF contact with water and/or solvent can increase number of such pin hole probability as microscopic can result under echanical stress by bending and/or stretching.