Magnet Wire: Considerations

What is magnet wire?

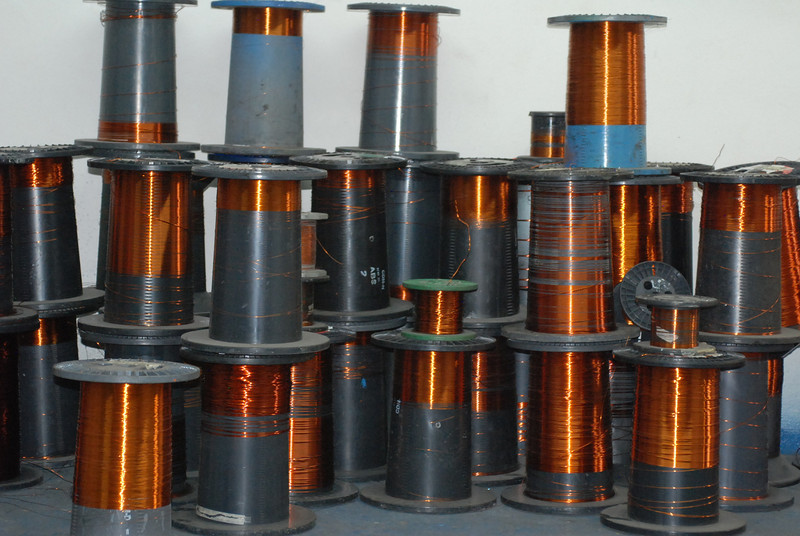

Magnet wire, or enameled wire, is a copper or aluminum wire covered with a very thin layer of insulation.

What is it for?

It is used in the construction of transformers, inductors, motors, speakers, hard drive head actuators, potentiometers, electromagnets, and other applications that require tight coils of wire.

What is the difference between copper and aluminum magnet wire?

Aluminum has a lower conductivity than copper, so aluminum wire needs a larger cross section to compensate. For this reason, copper wire is more energy efficient.

What is isolation and what is it for?

The insulation can be a thin varnish or enamel, a thread made of polyester, fiberglass, or both.

If the cable were bare, the turns of the cable could not not touch each other, since they would produce a short circuit, instead the insulated cable can be wound so that they do not touch each other. For a cable that will have hundreds or thousands of turns, insulation is absolutely necessary.

What are some of the common types used in magnet wire?

Different types of magnet wire insulation have different heat capacity, diameter (which can be measured in millimeters or inches), AWG wire size, and application.

Here are some common types of insulation and their specifications:

| insulation type | thermal class(°c) | Diameter (mm) | Diameter (in.) | AWG Wire Size Range | Applications |

| Polyurethane | 120

130 155 |

0.08 a 1.00 | 0.0031 a 0.0394 | 20-18 | Transformers, meters and communication devices. |

| Polyester | >155 | 0.08 a 1.6 | 0.031 to 0.063 | 20-14 | Motors in household appliances. |

| Polyester-imide | 180 | 0.1 a 1.00 | 0.0039 a 0.0394 | 38-18 | High power motors. |

| polyamideimide | 220 | 0.1 a 1.6 | 0.0031 a 0.063 | 38-14 | Small motors and transformers. |

| Poliuretano autoadhesivo | 130 | 0.08 a 1.2 | 0.0039 a 0.0394 | 20-16 | Communication devices and small motors. |

| self-adhesive polyester imide | 180> | 0.1 a 0.8 | 0.0039 a 0.031 | 38-20 | Magnetic coils and deflection yoke applications. |

| Polyamide coated polyurethane | 130

155 |

0.08 a 1.6 | 0.0031 a 0.063 | 20-14 | Small motors and transformers. |

| Polyamide coated polyester | >155

180 |

0.1 a 1.6 | 0.0039 a 0.063 | 38-14 | Small engines. |

| Polyester-imide coated with polyamide-imide | 200 | 0.1 a 1.6 | 0.039 a 0.063 | 38-14 | Microwave transformers and air conditioning motors. |

What is insulation thickness?

The insulation thickness, or structure, is the measurement of the enamel that has been added to the circumference of the wire. It can be determined by taking the total diameter of the wire and enamel together, and then subtracting the diameter of the wire from the total diameter.

The insulation construction can be single, heavy, triple, or quadruple, with single and heavy construction being the most common. The single insulation thickness for a 24 gauge wire may be 0.0010 inches and 0.0019 inches for a heavy structure. For 40 gauge wire, simple construction may be 0.0002 inches and 0.0006 inches for heavy construction.

Larger insulation constructions are used to strengthen the cable or to offer more protection.

What is American Wire Gauge (AWG)?

It is the American Wire Gauge (AWG) used in the United States and Canada to represent the diameter of round solid wire.

How does wire diameter affect gauge?

As magnet wire diameters decrease, the AWG number increases. For example, a wire with a diameter of 4.621 millimeters will have an AWG size of 5, while a wire with a diameter of 0.255 millimeters will have an AWG size of 30.

There are 44 standard wire sizes: 0000-40. Any wire size beyond those gauges will be so small that it will need to be measured in ohms.

How do I determine the weight of my cable?

Like the diameter, the wire weight is based on AWG standards. The weights of each caliber are standardized. As the gauge increases, the weight of the wire will decrease.

The largest wire weight is 640.5005 pounds per 1000 meters, with a gauge of 0000. For 40 gauge wire, the weight is 0.0299 pounds per 1000 meters.

What temperature classification / thermal class?

The thermal class, or temperature rating, is the maximum temperature to which the magnet wire can be exposed. The thermal class is measured in degrees Celsius. 130°C, 155°C, 180°C and 200°C are some common temperatures found in different types of insulation. The maximum thermal class is 250°C.

What is the difference between round and square magnet wire?

Square magnet wire will have less space between the wires when formed into a coil. For this reason, square wire is used in tight spaces. AWG ratings only apply to round wire.

Solid wire or stranded wire?

Solid magnet wire is a single strand of insulated wire. They do not bend easily and are used in applications where they are not moved frequently. Stranded magnet wires are multiple wires twisted together. These types of cables are flexible and easy to install.

What does the color of the magnet wire mean?

Magnet wire can come in a variety of colors, including red, green, and amber. However, this is purely cosmetic and will not influence how the cable will perform or its insulating properties.

What is bondable magnet wire?

The adhesive magnet wire has an additional adhesive film on top of the usual insulation. When the adhesive is activated, it will join the twist to convert the windings into a self-supporting coil.

What is solvent bondable magnet wire?

This type of bonding coat will either be applied while the wire is being wound or the wound wire will be dipped into the solvent after it has already been wound. The coil must then be heated again to complete the bond and dry any additional solvent.

Bondable magnet wire may not always be able to withstand the temperature rating of some insulations.

What is oven bonding?

After the wire is wound, the coil is placed in an oven which will allow the bonding layer to glue the wire. Bonding in the oven can take anywhere from 10 to 30 minutes, depending on the size of the wound wire.

What is resistance bonding?

Resistance bonding is very similar to oven heating, but in this case an electrical current is used to heat the coil. There is no uniform heating time for resistance bonding; voltage and time depend on wire size and coil design. This method is typically used for 34 gauge or larger wire.

Does magnet wire have a shelf life?

As long as it is carefully stored it should be usable for years. Sticky wires should not be stored at temperatures above 100°F.