Enamelled Wire

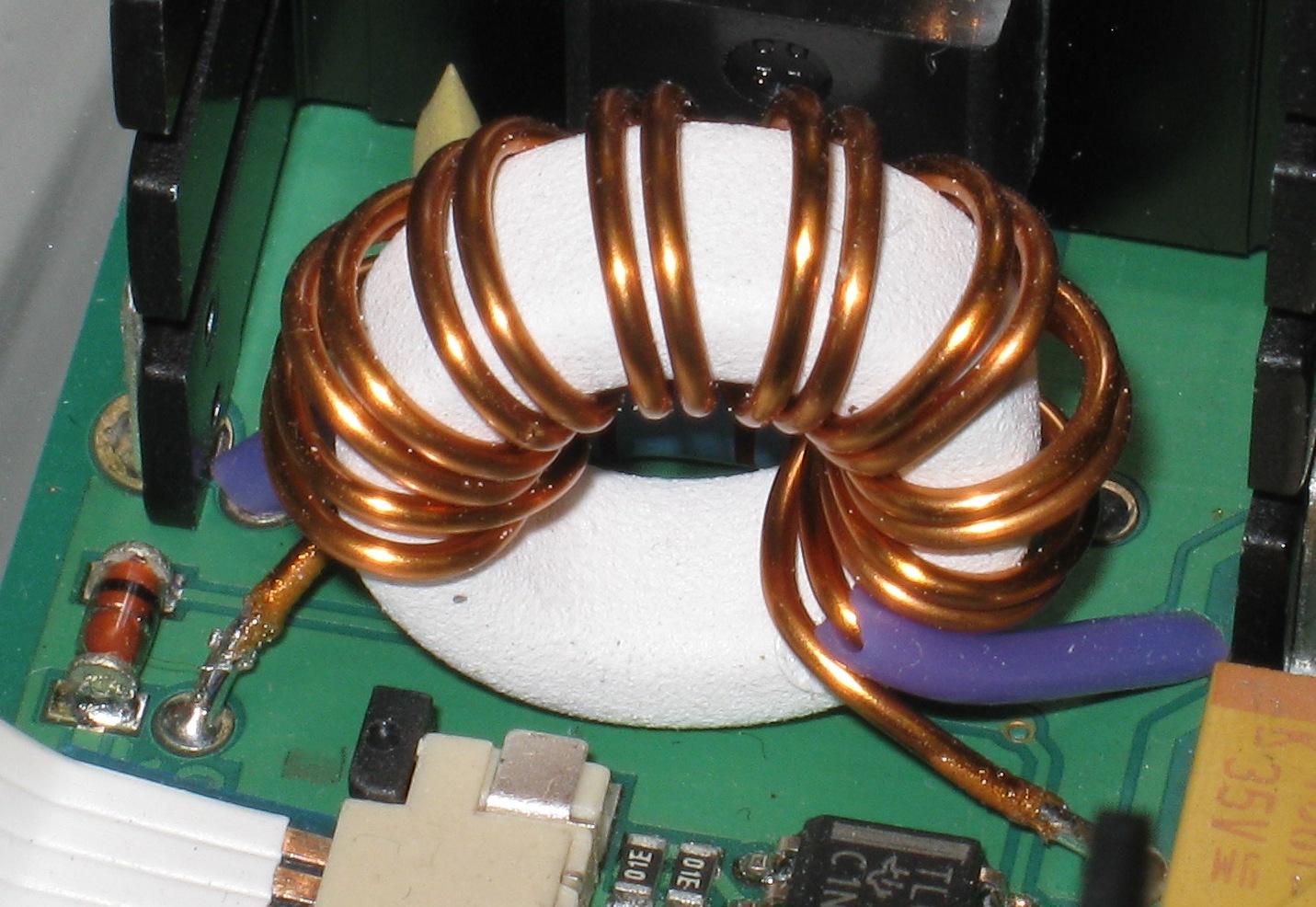

Enamelled wire, also referred to as enamel wire, magnet wire, winding wire, magnetic wire – a type of winding wire, usually made from copper or aluminium, insulated by a type of cured resin called enamel, and used for making windings and coils.

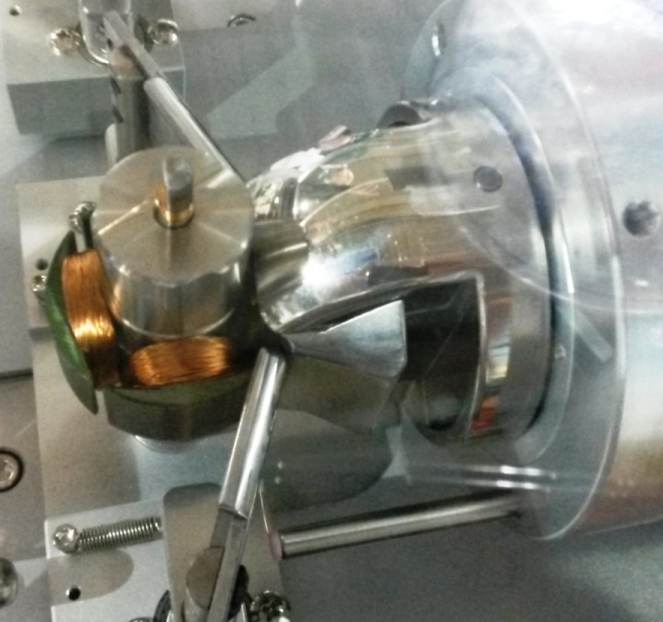

Enamelled wire with is widely used in windings of small and medium size electric motors and transformers, as well as other electromagnetic devices such as sensors and actuators.

Technical parameters

Despite its simple appearance, enamelled wire is a sophisticated product. The enamelled wire must withstand the mechanical stresses due to bending and stretching during coil winding, which is typically executed at the fastest speed possible in order to increase productivity.

Also, during nominal operation (and overload events) the mechanical forces, thermal stress, as well as chemical and environmental conditions require certain level of performance from the wire and its insulation, so that a reasonable life time can be expected.

The frequently used grades have their technical parameters standardised by international standards such as: IEC 60317, NEMA MW1000, and JIS C3202.

For example, for round enamelled wires the following parameters are defined or controlled:

-

dimensions such as diameter or size (e.g. for IEC should follow the R20 series with 1% tolerance on diameter and up to 10% tolerance on electrical resistance, see also: diameters of round enamelled wire)

-

adherence (e.g. the enamel should not crack after winding on a mandrel with diameter 0.15 mm or the same diameter as the wire)

-

mechanical flexibility (resistance of enamel to cracking)

-

elongation (due to tension required during winding, e.g. the enamel should not crack if wire 1.6 mm diameter is stretched by 32%)

-

heat shock resistance (no cracking after winding on a small-radius mandrel and exposing to sudden change of temperature)

-

spring back (maximum angle the wire is allowed to spring back after bending)

-

dielectric breakdown strength or breakdown voltage (the wire must withstand appropriate voltage, ranging from 110V for 0.018 mm wire Grade 1, to 7600 V for 2.5 mm wire Grade 3)

-

completeness of cure of the enamel (e.g. limited number of pinholes per given length)

-

solderability (ease of applying solder directly through the enamel)

-

thermoplastic flow or “cut-through” (minimum value at which electrical breakdown of insulation happens at elevated temperatures)

-

solubility (e.g. by applying standard solvent the coating should not be removed by scratching with a soft tool)

-

transformer oil resistance and hydrolytic stability

-

bonding quality (of the bonding coating, where applicable)

-

thermal endurance (at elevated temperatures)

-

scrape resistance of the enamel

-

loss of mass

-

electrical resistance

-

lap shear bond strength

Enamel properties

Apart from electrical insulation, the enamel also provides protection against corrosion or oxidation of the copper wire.

Typical electric strength of the enamel is around 170-220 V/μm, which is why a relatively thin layer of enamel can withstand significant voltage. For example, the 0.375 mm wire with the cracked enamel shown above has a voltage breakdown of 4.35 kV despite the enamel thickness being only 0.0275 mm.

The life span of electrical insulation is related to the temperature at which it is used. A typical minimum lifetime of enamel in its nominal temperature is at the order of 20 000 hours.

There are several nominal temperature ranges (thermal classes), listed with the basis on which the enamel is made, for example:

-

155-180°C – polyurethane (good solderability at 370-390°C)

-

180-200°C – polyesterimide (good thermal and chemical resistance, solderable above 470°C)

-

220°C – polyamidimide (good thermal and mechanical resistance, not solderable through enamel)

-

240°C – aromatic polyimide (very good thermal, chemical and radiation resistance, not solderable through enamel)

Soldering

The presence of enamel impedes soldering (as compared to bare copper). For this reason, the chemical properties of enamel are optimised in order to facilitate soldering (especially for the enamels rated up to 200°C), which can be achieved by direct application of heat and solder to the outer surface of the enamelled wire.

The enamel will dissolve or boil off, exposing the copper underneath, and to some extent providing even some fluxing or self-fluxing properties. This is sometimes indicated in the name of the product, for example “Polysol” of Elektrisola.

The enamel rated for higher temperatures does not support the action of direct soldering through to the copper. Instead, the coating has to be removed by some mechanical means first.

Self-bonding enamelled wire

There are also special grades of enamel for specific applications. For example, there is “self-bonding” type of enamel which has an additional layer of adhesive.

After a winding is made, the formed wires can be made to adhere to each other, by activating the adhesive with a solvent or warming up the assembly. With the thermal method the coil can be warmed up (depending on the type of the bonding agent), typically to around 120-220°C by: blowing hot air on the assembly, putting it in an oven, or by the “resistive method” (passing current through the coil to heat it up).

With the solvent method, the adhesive can be activated by applying (brushing, spraying or wicking) a suitable solvent such as denatured alcohol (ethanol or methanol), during the winding process. The solvent may be diluted with water, as required, but the strength of bonding is reduced.

Grades

Enamel wire is typically made in three “grades”, with the number related to the thickness of enamel (sometimes assumed to be the number of coating layers, but in reality there can be more layers):

-

Grade 1 – thinnest insulation (single coating)

-

Grade 2 – medium insulation (double coating)

-

Grade 3 – thickest insulation (triple coating)

Grade 3 of enamelled wire should not be confused with triple-insulated wire.

Production

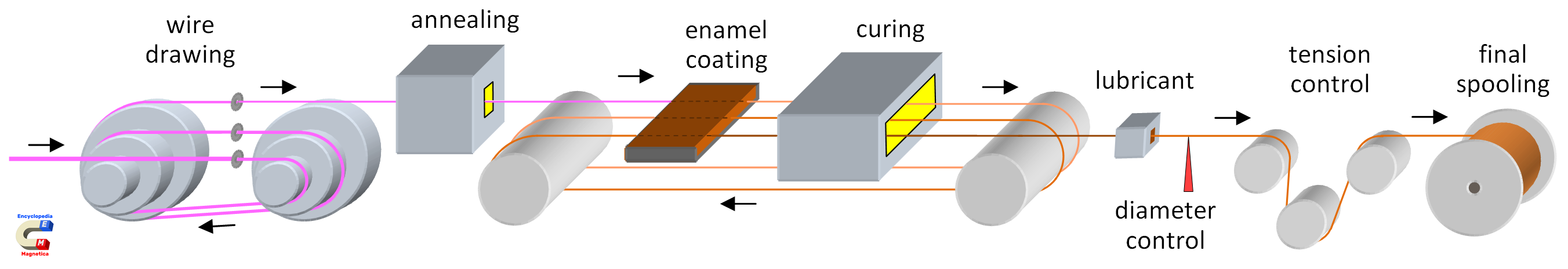

The production process involves several stages:

-

drawing the wire – from a thicker gauge to the target diameter (in several steps)

-

annealing – to remove mechanical stress

-

coating – with raw enamel (liquid resin)

-

curing – drying off the volatile content of the resin and forming the polymer links

-

applying lubricant – for easing further mechanical processing

-

quality control – checking the diameter of the manufacture wire

-

final spooling – on standardised reels, ready for shipping to the final user