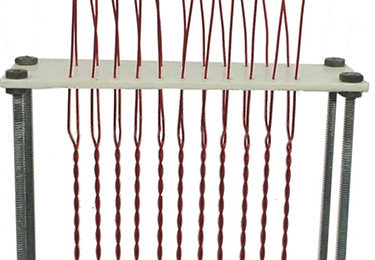

THEIC Modified Polyesterimide Wire Enamels

is class 180 THEIC modified polyesterimide wire enamel with temperature index 200.

provides improved flexibility & adherence to copper.

gives excellent resistance to refrigerants hermetic motors.

can be used as base coat for manufacturing dual coating wires with Polyamide-Imide.

suitable for high speed enamelling machines up to 200VD.

Theic modified Polyesterimide enamel used as a single coat as well as for dual coat wires. It is recommended for thicker gauges. Wires combined with Polyamide – Imide enamel have excellent resistance against chemicals including refrigerants & suitable for application in hermetic motors.

PHYSICAL PROPERTIES

This Modified Polyester Baking Enamel is a versatile, low temperature curing industrial finishing enamel for manufacturers of metal products.

| PHYSICAL PROPERTIES | |||

| Appearance | Clear Liquid | ||

| Solid Content 1g/1800C/1h |

36 ± 1% | 40 ± 1% | 45 ± 1% |

| Size mm |

0.05 to 0.500 |

0.5 to 2.0 |

1.6 to 5.0 |

|

* Viscosity |

40 -50 |

70-100 |

100-120 |

|

** Viscosity |

300 – 400 |

650 – 1000 |

1500 -2000 |

| PROPOSED Machine |

horizontal machine for felt |

horizontal vertical plant for die |

vertical plant for die |

| Flash Point |

400C |

||

| Compatibility with thinner |

1 : 1 |

||

MECHANICAL & CHEMICAL PROPERTIES

| MECHANICAL PROPERTIES | |

| Diameter of Bare wire | 1.0 mm |

| Build up of enamel | 0.070 mm |

| Elongation | 36% |

| Flexibility Mandrel Winding (15% pre stretch 1xd) |

OK |

| Jerk Test | OK |

| Peel Test (nXd) | 160 – 180 |

| Abrasion (Av) (Unidirectional) |

14N |

| CHEMICAL PROPERTIES | |

| Solvent Resistance | |

| Pencil Hardness | |

| Initial | 3h |

| Std. Solvent | 2h |

Bending

| Tan Delta |

|

| Bending Point oC(Solid Block) |

195-210 |

| THERMAL PROPERTIES |

|

| Heat Shock 2d/200 0C/ 30min |

OK |

| Cut Through 3400C / 2min |

OK |

| THERMAL PROPERTIES |

|

| Heat Shock 2d/200 0C/ 30min |

OK |

| Cut Through 3400C / 2min |

OK |

| ELECTRICAL PROPERTIES |

|||

| Break Down Voltage kV | at RT | 10.0 | |