Super Enameled Copper Wire Shipped to Bangladesh

technical specification of super enameled copper wire

1. conductor size

| SL.NO | CONDUCTOR SIZE | NOMINAL DIA IN MM |

| 01 | SWG-14 | 2.032 |

2. conductor dimensions

| SL.NO | SIZE | TOLERANC(mm) | AREA OF CONDUCTOR | OVERALL DIA IN WITH INSULATION |

| 01 | SWG-14 | ±0.021 | 3.243 | 2.153 |

3. insulation

i) The insulation film should be uniform and have superior electric properties.

ii) The insulation film should have superior mechanical and heat resistance properties.

iii) Enamel varnish should be done as per IEC 60317 part 3 or BSS-4516 BDS. 1035/1983 or its equivalent latest international standard.

4. conductor

(a)The wire to be manufactured from ingots with copper content not less than 99.9%resistivity 0.01724 ohm-mm”/meter at 20 C.

(b) Tensile Strength: 20 Kgf/mm2 (Minimum)

(c) Relative Elongation 25% (Minimum)

(d)The conductor should be sufficiently annealed and straightened without any physical defects, such as twisting, cracked and scratched etc&should be soft, flexible and smooth surface for efficient winding.

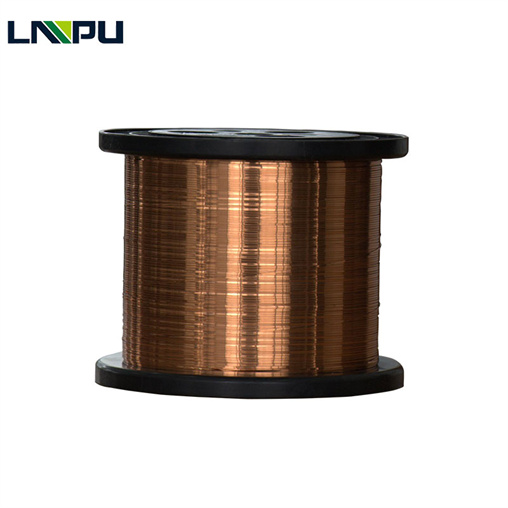

5. packing

a) The wire should be supplied in plastic/wooden Bobbin with size as following: Dimension of Reel/Bobbin:

1. Diameter of flange 420 mm (Maximum)

2. Thickness of flange 30 mm (Minimum)

3. Outer width of Reel/Bobbin: 155mm

4.Center hole dia:35mm to 45mm(Hole for mandrel)

b) Net weight of conductor per bobbin should not be less than 40 Kg Maximum 50Kg.

c) The number of pieces of wire in each bobbin should be single.

d)The bobbin should be packed in suitable water proof packing in wooden container of Export standard Seaworthy,suitable for handling for transportation by road,Rail Sea.