Self-lubricating Enameled Wire

A enameled wire having 100 parts by weight of a polyamide-imide resin, 1 to 5 parts by weight of a lubricant, 1 to 200 parts by weight of a masking agent-stabilized isocyanate, and 1 to 30 parts by weight of a silane coupling agent are dissolved or dispersed in a solvent to prepare a coating composition. The coating composition is then coated directly or through other insulator on the circumference of a conductor, and the coating is then baked to form a lubricating layer.

Description

FIELD OF THE INVENTION

The present invention relates to a self-lubricating enameled wire, and more particularly to a self-lubricating enameled wire provided with a lubricating layer which is excellent in surface lubricity, abrasion resistance and adhesion to varnish as a treating agent.

BACKGROUND OF THE INVENTION

In recent years, for the purposes of reducing the size of equipment, increasing coil winding speed, and reducing inferior quality ratio of coils, it is required for an enameled wire for use in coils of electric or electronic equipment such as motors and transformers to have excellent surface lubricity and abrasion resistance which enable winding under severe conditions.

In particular, according to recent requirements to improve efficiency of motors from the viewpoint of energy saving, it is required for an enameled wire for use in high-space factor motors to have further improved surface lubricity and abrasion resistance.

The following methods (1) to (3) may be mentioned as conventional methods for improving the lubricity and abrasion resistance of enameled wires.

(1) A method wherein a lubricating material composed mainly of paraffin or a fatty acid ester is coated on the surface of enameled wires optionally followed by baking.

(2) A method wherein either a nylon resin having excellent lubricity or a coating composition prepared by adding a lubricant, such as low-molecular weight polyethylene, to a nylon resin is coated on the circumference of a conductor through other insulating layer, followed by baking of the coating.

(3) A method wherein a coating composition prepared by adding a lubricant component, such as polyethylene wax or a fatty acid ester, to an insulating coating composition containing, for example, a polyester or a polyamide-imide is coated on the circumference of a conductor through other insulating layer, followed by baking of the coating.

On the other hand, coils for use, for example, in motors and transformers, are treated with varnish, such as epoxy and unsaturated polyester, from the viewpoint of improving band strength and insulating properties of the coils.

The enameled wires, which have been subjected to lubrication treatment by the methods (1) to (3), however, are disadvantageously inferior to adhesion to the varnish as the treating agent in comparison with conventional enameled wires not subjected to lubricating treatment.

For this reason, in order to improve the reliability of coils, the development of self-lubricating enameled wires having excellent adhesion to varnish as the treating agent has been desired in the art.

SUMMARY OF THE INVENTION

Accordingly, it is an object of the invention to provide a self-lubricating enameled wire which possesses excellent lubricity, abrasion resistance, and adhesion to varnish as the treating agent.

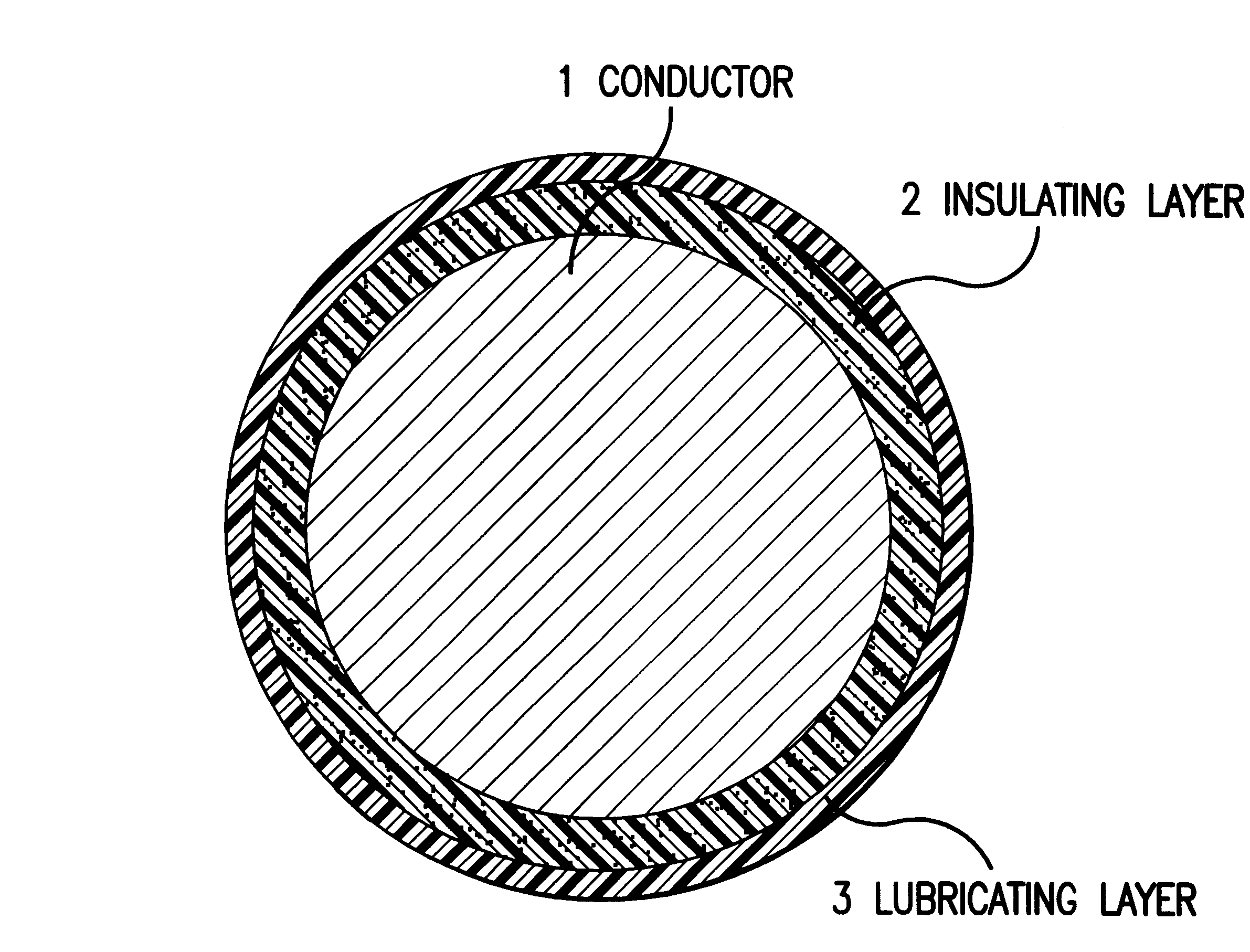

According to the first feature of the invention, a self-lubricating enameled wire comprising a conductor and a lubricating layer formed on the circumference of said conductor directly or through other insulating layer by coating and baking a coating composition, said coating composition comprising 100 parts by weight of a polyamide-imide resin, 1 to 5 parts by weight of a lubricant, 1 to 200 parts by weight of a masking agent-stabilized isocyanate, and 1 to 30 parts by weight of a silane coupling agent, and dissolved or dispersed them in a solvent.

According to this constitution, the lubricating layer is formed by coating and baking a coating composition which is dissolved or dispersed, in a solvent, a polyamide-imide resin having excellent mechanical strength, a lubricant and a stabilized isocyanate for imparting lubricity and abrasion resistance, and a silane coupling agent for imparting the adhesion to varnish as the treating agent. Therefore, mixing of these various components in respective predetermined amounts can realize self-lubricating enameled wires possessing excellent lubricity, abrasion resistance, and adhesion to varnish as the treating agent.

Our Products

Customer Industries