Introduction

Polyphenylsulfone (PPSF or PPSU) is a high performance polymer made of aromatic rings linked by sulfone (SO2) groups. Polyphenylsulfone (PPSU, PPSF) is an amorphous, heat-resistant and transparent high-performance thermoplastic synthesized by nucleophilic aromatic substitution between difluorodiphenyl sulfone and the sodium salt of 4,4-dyhydroxybyphenyl with elimination of sodium fluoride. The biphenylene ether unit of PPSU markedly increases the impact strength and reduces the notch sensitivity, resulting in high notched (Izod) impact values which exceeds those of other polysulfones (PSU, PES).2 It also contributes to ease of melt fabrication. In fact, these resins can be readily injection molded or extruded on conventional equipment. However, processing requires relative high mold temperature of at about 365 to 395°C whereas glass fiber reinforced grades require even higher temperatures.

Polyphenylsulfone Characteristics

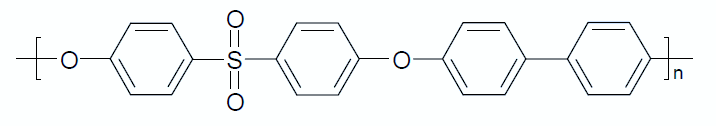

PPSU is the abbreviation for Polyphenylsulfone. Also known as PPSF, PPSU is a new member of the sulfone polymers family that has multiple attractive properties such as high-temperature performance, good chemical resistance (maintaining its original properties after being exposed to a harsh chemical environment pH at 1–13), outstanding toughness, corrosion resistance, chlorine tolerance, excellent colorability, and very good dimensional stability . The polymer can be distributed in two different families depending on the level of the molecular organization of the constitutive chains at the microscopic level. Compared to other sulfone polymers, PPSU is an amorphous polymer. Therefore, it features very good creep resistance, isotropic thermal and mechanical properties, and transparency. PPSU consists of an aromatic unit (phenylene) chain with a sulfone group and a benzene ring, connected by an oxygen atom. Due to this conjugated structure, the rigidity of the material can be maintained, and it gives good liquidity [28][50]. Figure 3 shows the molecular structures of PPSU.

Production

Commercially important polysulfones are prepared by condensation of 4,4′-bis(chlorophenyl)sulfone with various bisphenols. Two bisphenols for this application are bisphenol A (the polymer being called PSF) and 4,4′-bis(4-hydroxyphenyl)sulfone (the polymer being called PES). PPSU is the highest performing polysulfone. It is known for its high toughness, high flexural and tensile strength, excellent hydrolytic stability and good resistance to chemicals and heat. Compared to the two other polyethersulfones PSU and PES, it has superior mechanical properties, but it is also more expensive, and thus, less widely used. It also has the best chemical resistance of all polyethersulfones. For example, it is highly resistant to aqueous mineral acids, bases, and oxidizing agents and most solvents. However, aromatic solvents and oxygenated solvents, such as ketones and ethers, might cause some stress cracking.

Applications

PPSF is a moldable plastic often used in rapid prototyping and rapid manufacturing (direct digital manufacturing) applications. Polyphenylsulfone is heat and chemical-resistant suited for automotive, aerospace, and plumbing applications. Polyphenylsulfone has no melting point, reflecting its amorphous nature, and offers tensile strength up to 55 MPa (8000 psi). Its commercial name is Radel. In plumbing applications, polyphenylsulfone fittings have been found to sometimes form cracks prematurely or to experience failure when improperly installed using non-manufacturer approved installation methods or systems. PPSU is often an excellent choice for components that are exposed to high temperatures and corrosive media because it has exceptional chemical resistance. Examples include pipe fittings, battery containers, medical device parts, and sterilizable products for health care and nursing. Polyphenylsulfone is also used in the automotive and aerospace industries for applications where superior thermal and mechanical properties relative to conventional resins are required. However, most (unfilled) grades are not suitable for outdoor uses because of poor weathering, ozone and UV resistance.