PFA 4 Wire: An Overview of a Precise Electrical Connection

Introduction

In the realm of electrical connections and measurements, accuracy and reliability are paramount. To ensure precise resistance or impedance measurements, a configuration known as PFA 4 Wire is commonly employed. In this blog post, we will explore the meaning and significance of PFA 4 Wire, shedding light on its application and benefits.

Understanding PFA

Before delving into PFA 4 Wire, let’s first familiarize ourselves with the material itself. PFA stands for Perfluoroalkoxy, which is a type of fluoropolymer renowned for its exceptional chemical resistance, high thermal stability, and low coefficient of friction. PFA is widely used in numerous industrial applications, particularly for its remarkable properties that make it an ideal choice for wire and cable insulation.

The Concept of 4 Wire

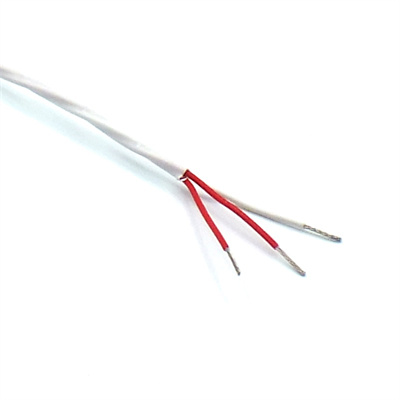

The “4-wire” configuration signifies an electrical connection or measurement setup involving four separate conductive wires. In the context of PFA 4 Wire, it indicates the utilization of PFA-insulated wires within a four-wire electrical system. This configuration plays a pivotal role in achieving accurate measurements, especially when it comes to resistance or impedance.

Why Use 4 Wire?

When conducting electrical measurements, particularly those involving low resistance values, the resistance of the measurement leads or wires can introduce errors. These errors occur due to the voltage drop along the measurement leads, which can significantly affect the accuracy of the readings. The 4-wire configuration addresses this issue by compensating for the resistance of the wires themselves.

Components of a PFA 4 Wire System

A typical PFA 4 Wire system consists of four wires, each with a specific function:

Current-Carrying Wires: These wires are responsible for supplying the current used in the measurement. They transmit the current through the device or component being tested.

Sense Wires: The sense wires are used to measure the voltage drop across the component or device under test. By connecting the sense wires as close as possible to the measurement points, they effectively compensate for the resistance in the current-carrying wires.

Benefits of PFA 4 Wire

The implementation of PFA 4 Wire offers several significant benefits:

Increased Accuracy: By compensating for the resistance of the measurement leads, the 4-wire configuration provides highly accurate measurements, particularly in low-resistance applications.

Error Minimization: The use of sense wires effectively reduces the errors caused by voltage drop along the measurement leads, enhancing the reliability of the measurements.

Enhanced Precision: PFA 4 Wire enables precise resistance or impedance measurements, ensuring reliable data for analysis, testing, and calibration purposes.

Wide Applicability: PFA 4 Wire finds application in various industries, including electronics, telecommunications, engineering, research laboratories, and manufacturing, where accurate measurements are crucial.

Conclusion

PFA 4 Wire, which combines the benefits of PFA insulation and the 4-wire configuration, plays a crucial role in achieving accurate and reliable electrical measurements. By compensating for the resistance of the measurement leads, this setup ensures precision in resistance or impedance measurements, making it a valuable tool in various industries.

Whether in the electronics, telecommunications, or research fields, the utilization of PFA 4 Wire offers increased accuracy, minimized errors, and enhanced precision. As technology advances and precision becomes increasingly vital, PFA 4 Wire will continue to play a significant role in delivering accurate electrical measurements for countless applications.