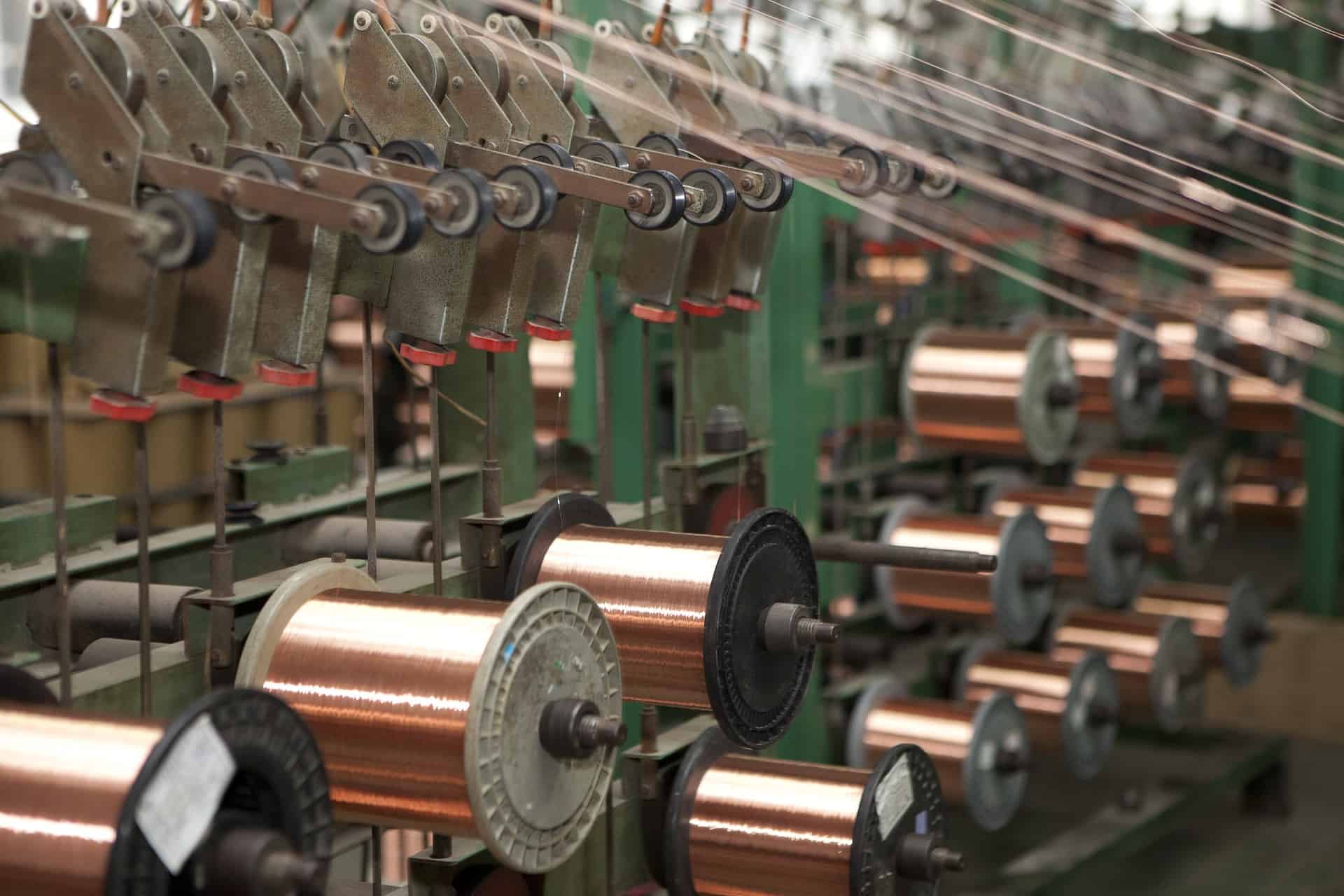

Enameled Wire Product Classification

Enameled wire products are widely used in a range of industries, including electronics, telecommunications, and automotive manufacturing. They are used to make motors, transformers, generators, and other electrical components that require high levels of electrical conductivity and durability. Enameled wire products are classified based on their size, insulation thickness, and type of insulation used. In this article, we will discuss the different types of enameled wire products and their classification.

Size Classification The size of enameled wire products is measured by their diameter in millimeters or gauges. The American Wire Gauge (AWG) system is commonly used in the United States to classify wire sizes. The AWG system assigns a number to each wire size, with larger numbers indicating smaller wire sizes. For example, a wire with an AWG size of 22 has a smaller diameter than a wire with an AWG size of 18.

Insulation Thickness Classification Enameled wire products are also classified based on the thickness of their insulation. The insulation thickness is measured in microns (μm) or mils (thousandths of an inch). The thickness of the insulation is critical to the wire’s ability to withstand electrical current and mechanical stress. Thicker insulation provides better protection against wear and tear, while thinner insulation is more flexible and easier to work with.

Type of Insulation Classification Enameled wire products can be classified based on the type of insulation used. There are three main types of insulation used in enameled wire products:

- Polyurethane (PU) Insulation: PU insulation is a high-performance insulation material that offers excellent thermal and electrical properties. It is resistant to chemicals, solvents, and moisture, making it ideal for use in harsh environments. PU insulation is commonly used in motor winding applications.

- Polyester (PE) Insulation: PE insulation is a cost-effective insulation material that offers good electrical properties and excellent resistance to abrasion and temperature changes. It is commonly used in low-voltage applications, such as transformers and solenoids.

- Polyamide (PA) Insulation: PA insulation is a high-temperature insulation material that offers excellent resistance to heat and chemicals. It is commonly used in high-temperature applications, such as ovens, heaters, and furnaces.

Conclusion

In conclusion, enameled wire products are an essential component of many electrical devices, and their classification is critical to their proper use. The classification of enameled wire products is based on their size, insulation thickness, and type of insulation used. Understanding these classifications is essential to selecting the right enameled wire product for a given application. When choosing an enameled wire product, it is important to consider the application’s requirements and the wire’s electrical and mechanical properties to ensure optimal performance and reliability.