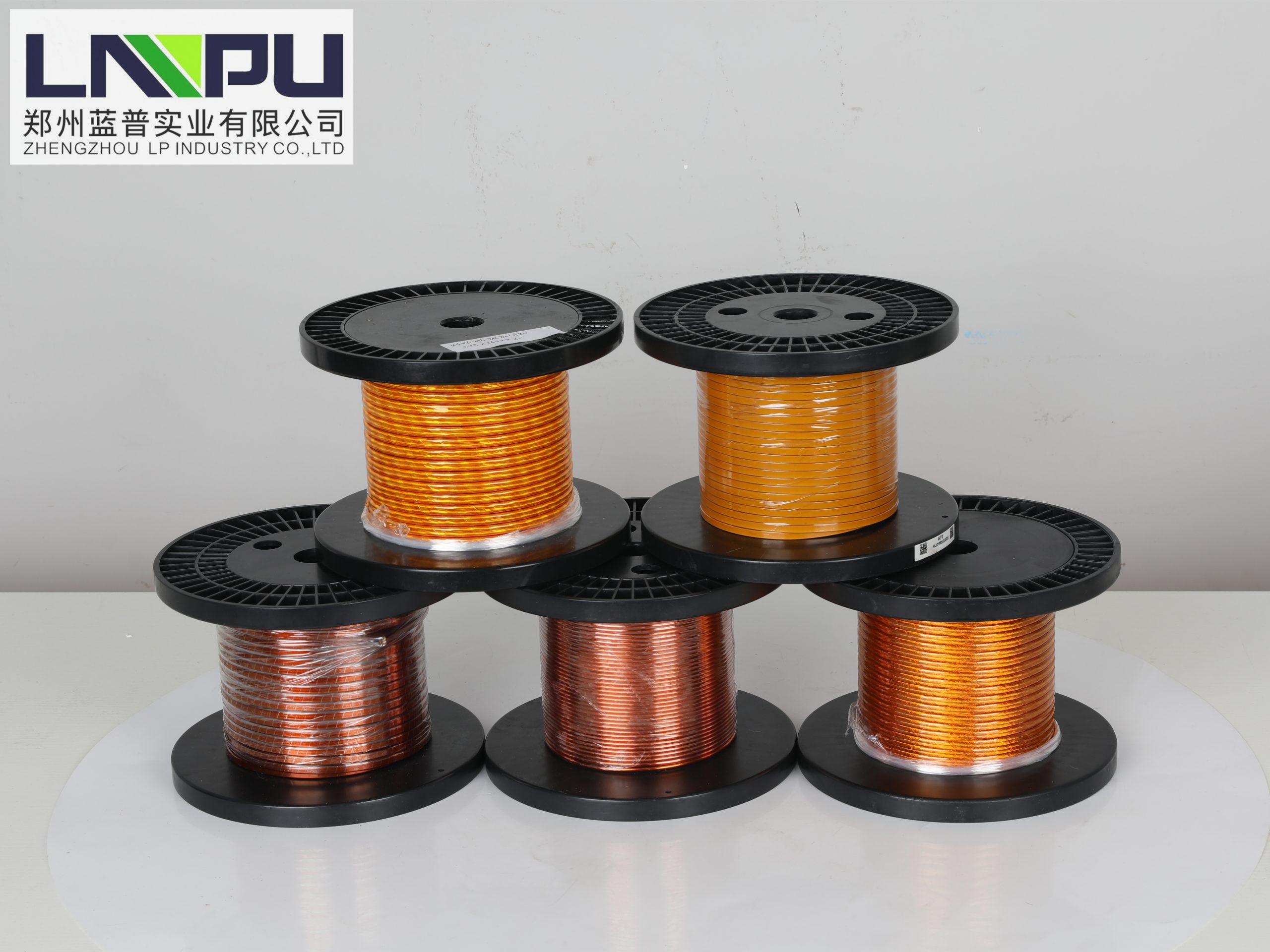

Enameled Wire (Focus on Enameled Wire for New Energy Vehicles)

1.Product Name: Enamelled flat wire (copper/aluminum)

2.Variety:

| serial number | model | name |

| 1 | Q(ZY/XY)B | Class 200 Composite Insulated Enameled Wire |

| 2 | Q(ZY/XY)B | Grade 220 Polyamideimide Enamelled Wire |

| 3 | Q(Y(F)/XY)B | Class 220 Composite Insulated Enameled Wire |

| 4 | Q(ZY/XY)NB、QXYNB | 200/220 grade self-adhesive vertical winding enameled wire |

| 5 | QY(F) B | Class 240 Aromatic Polyimide Enameled Wire |

| 6 | QY(F) B | Class 240 High PDIV Magnet Wire |

| 7 | Q(ZY/XY)BPB、QXYBPB、QY(F) BPB | 200/220/240 class corona resistant enameled wire |

| 8 | QY(F) BPB | Class 240 High PDIV Extra Long Corona and Oil Resistant Magnet Wire |

| 9 | MYFQY(F)B | Class 240 enamelled film-coated sintering line |

| 10 | / | Shaped enameled wire |

3. Electrical performance: After 2a and 2b are bent, the steel ball voltage test shows that the breakdown voltage is ≥14000v

Salt water withstand voltage: 8000v, withstand voltage duration: 1min pass rate: 100%

4. Softness: Rebound≤4.5°

5. Insulation adhesion performance: cut and stretch 10%, the insulation film is separated from the conductor length ≤ 0.5b

6. Mechanical properties: 2a, 2b bending, no cracking, no delamination, no shedding of the insulation layer

Conductor elongation: ≥32%

7. Dielectric loss value: ≥330°C

8. PDIV: ≥2200V

9. Uniformity of paint film: 1.0~1.2

10. Corona resistance performance: ≥1000h

Main features: 1. Production specification range: a=0.5~5.6, b=1.25~16mm, the maximum thickness of the paint film on both sides can be 0.35mm;

2. The paint film has excellent uniformity and high reliability insulation;

3. The paint film has good flexibility and adhesion, which is suitable for coil forming processing;

4. Magnet wire used in high-voltage drive motors has high PDIV value, super long corona resistance performance, and excellent oil resistance;

5. Special-shaped enameled wires of various shapes can be made.

Application: Suitable for transformers, new energy vehicle drive motors, generators, inverters, aerospace motors, nuclear power motors, etc.

winding.