What's the Bondable Enamel?

Bondable Enamel is a kind of composite material that allows inorganic glassy material to be fused onto the substrate metal and firmly bound to the metal. The lead is aluminum or copper wire. Wires contain an additional adhesive film on top of the usual insulation layer, which activates when heated, resulting in what is called a bonding wire. It comes in different types, depending on the ingredients used, such as polyamides, imides, and polyester imides. It is used to protect tight coils manufactured in applications such as inductors, transformers, motors, loudspeakers, hard disk head actuators or enameled wires.

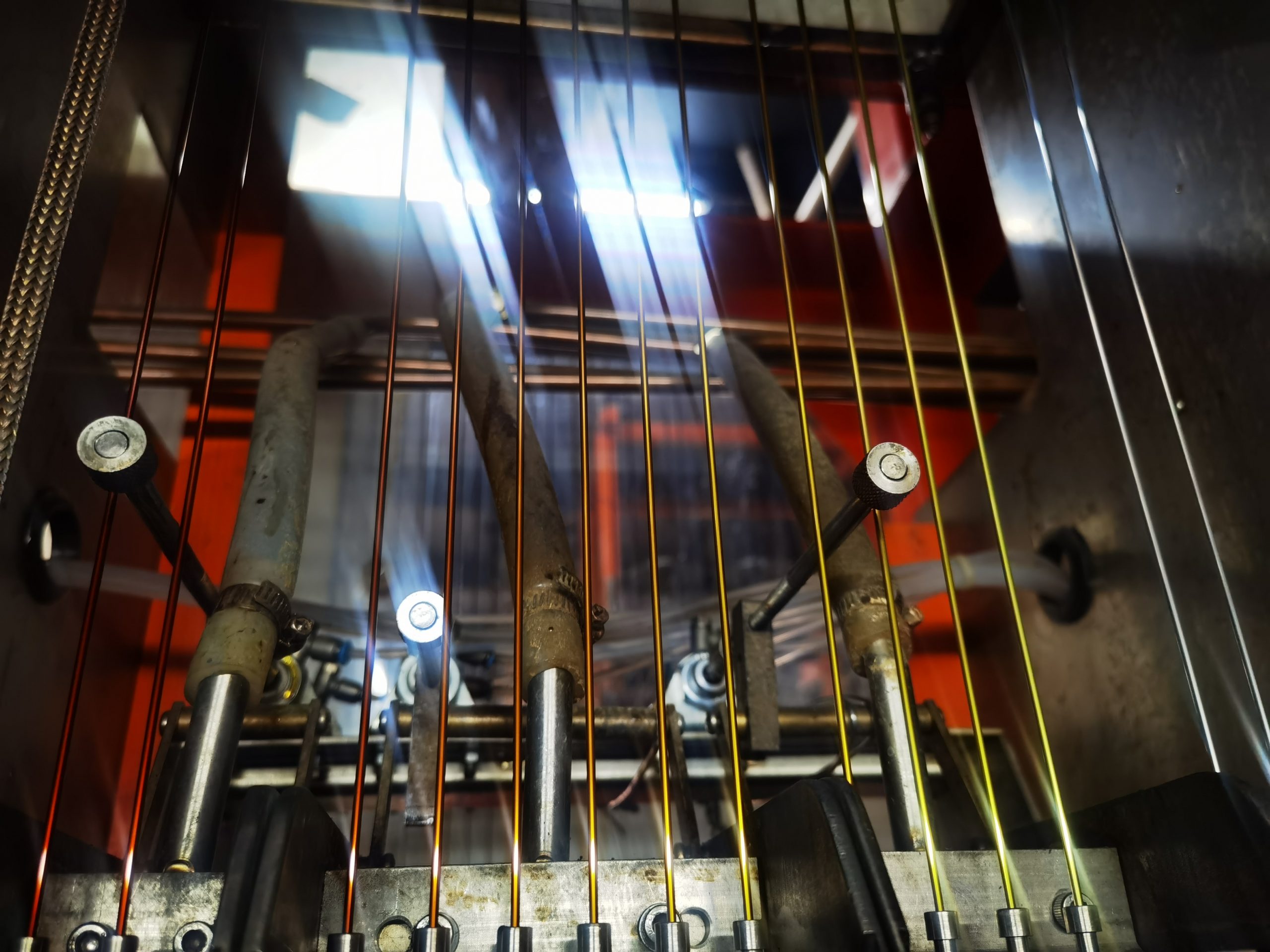

Production Methods - Bondable Enamel

Bondable enamel covers the coil at 140-220°C depending on the material, it has excellent bonding strength and moisture resistance. Resoftening at around 130-140°C. Polyamides are composed of polyimide resins. It is resistant to chemical solvents and burn out. It has a high capacity to withstand overload and the ability to be unaffected by varnish solvents, imides, used in inverter loads and motor applications where voltage spikes may occur. Polyester imide, with high heat resistance and solvent resistance. Because of the low friction force, it has higher winding ability. The Bondable core has 130 heat rating, good flexibility and wear resistance. This means it is usually used in harsh conditions.

Advantage - Bondable Enamel

Solute, torrefy and resistance bonding are the three main techniques for making bondable enamels. The solvent bonding coating can be applied during the winding process, or it can be applied to the finished coil by dipping the paint in the solvent. Torrefy bonding requires the wire to be completely wound before heating in the oven. The size of the coil will determine whether the torrefy bonding time is between 10 and 30 minutes. Resistance bonding is similar to oven bonding, but uses an electric current to heat the wire instead of the oven. The time required to complete the process depends on the size of the wire and the design of the coil. Resistance bonding is used for wires 34 gauge or higher.