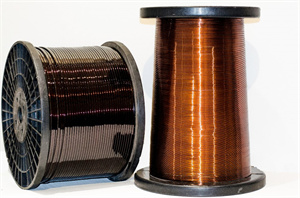

1.5mm copper conductor double coated polyesterimide enameled wire

Enameled copper wire, a vital component in various industries, plays a crucial role in electrical applications. This article delves into the world of enameled copper wires, with a particular focus on the 1.5mm copper conductor double coated polyesterimide enameled wire. Understanding its applications and significance in diverse fields is essential to appreciate its role in powering our modern world.

Where are Enameled Wires Used?

Enameled wires find application in a myriad of industries, owing to their unique properties. The primary function of these wires is to conduct electrical currents while providing insulation to prevent short circuits. Common applications include:

Electronics Manufacturing: Enameled copper wire is extensively used in the production of electronic components such as transformers, inductors, and motors. Its excellent electrical conductivity and insulation properties make it an ideal choice for winding coils.

Automotive Industry: In the automotive sector, enameled copper wire is employed in various electrical systems and components. From ignition systems to sensors, these wires facilitate efficient electrical connectivity in the complex network of an automobile.

Power Generation and Distribution: Enameled wires play a vital role in power generation and distribution. They are used in the construction of transformers, generators, and other equipment crucial for transmitting electricity across grids.

Appliances Manufacturing: Household appliances like refrigerators, washing machines, and air conditioners rely on enameled copper wires for their internal wiring. The wires’ thermal resistance and durability contribute to the reliable performance of these appliances.

1.5mm Enameled Copper Wire Can Be Used For:

The 1.5mm enameled copper wire holds a unique position due to its specific size and characteristics. This diameter is particularly versatile and finds applications in various scenarios:

Coil Winding: The 1.5mm diameter is well-suited for coil winding applications, offering an optimal balance between size and conductivity. This makes it a preferred choice for manufacturing efficient and compact coils used in transformers and inductors.

Motor Windings: Motors of various sizes benefit from the use of 1.5mm enameled copper wire for their windings. The wire’s size ensures efficient space utilization while maintaining the necessary electrical conductivity for motor functionality.

Electromagnetic Components: Components such as solenoids and relays often require a specific wire diameter for their windings. The 1.5mm enameled copper wire fulfills these requirements, ensuring reliable and precise performance in electromagnetic applications.

Application

The 1.5mm copper conductor double coated polyesterimide enameled wire, with its unique properties, caters to specialized applications:

High-Temperature Environments: The polyesterimide coating provides exceptional thermal resistance, making this wire suitable for applications in high-temperature environments. Industries such as aerospace and manufacturing processes benefit from its ability to withstand extreme heat.

Oil and Chemical Resistance: The double coating enhances resistance to oil and chemicals, expanding the range of applications to industries where exposure to corrosive substances is common. This makes the wire suitable for use in chemical plants and machinery operating in harsh environments.

Precision Instrumentation: Applications that demand precision and reliability, such as medical devices and scientific instruments, utilize the 1.5mm copper conductor double coated polyesterimide enameled wire. Its stable electrical properties contribute to the accuracy of these instruments.

Conclusion:

In conclusion, enameled copper wire, particularly the 1.5mm copper conductor double coated polyesterimide enameled wire, plays a pivotal role in diverse industries. From electronics and automotive to power generation, its applications are vast and varied. The 1.5mm diameter, with its specific characteristics, further extends the utility of enameled copper wire, proving its significance in modern technological advancements. As industries continue to evolve, the demand for specialized enameled wires is expected to grow, further emphasizing their indispensable role in our interconnected world.