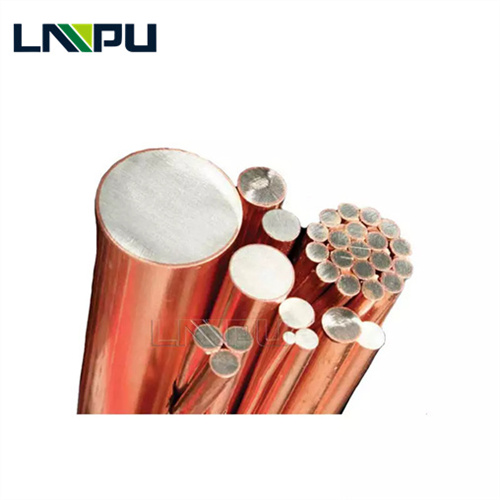

Copper-clad aluminum wire is made of a solid aluminum core covered with a copper skin in order to improve its performance in the field. This product was installed in homes in the United States between 1972 and 1975.

In fact a small amount of the copper cladding was smeared across the cut wire-end by the wire-cutting process as you might notice at the lower edge of the cut edge above the “COR” in the word “CORE”.

Copper clad aluminum electrical wire is comprised of a solid aluminum core covered with a thin clad of copper. Approximately 10 percent of the cross-sectional area of the conductor is copper clad, thickness is not specified.

This product (only wire size Nos. 12-10 AWG), was designed by Texas Instruments for use with standard copper-only wiring devices, ie. switches, receptacles (binding head screw, back-wired, and pressure plate type terminals) and was treated as “aluminum” conductor for use in AL-CU pressure wire connectors in response to field failures of solid aluminum conductor branch circuit wiring.

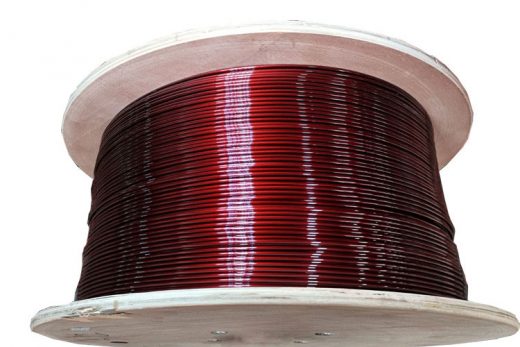

In a word, you could come to see Lanpu’s enameled copper clad aluminum wire.