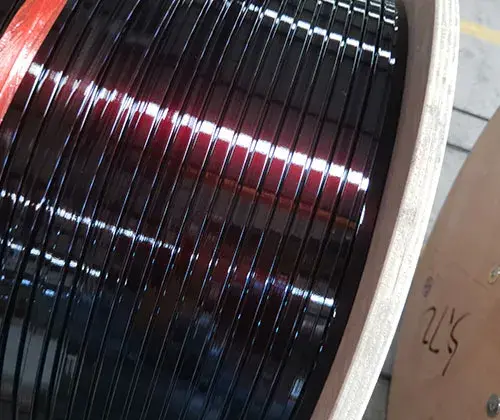

200°C Polyimide Rectangular Aluminum Enamelled Wire

Introduction:

In the realm of electrical engineering, the demand for high-performance wiring solutions is ever-increasing. One such remarkable innovation that has garnered attention in recent years is the 200°C polyimide rectangular aluminum enamelled wire. This cutting-edge wire combines the superior thermal resistance of polyimide with the conductivity of aluminum, resulting in a versatile and efficient electrical conductor. In this blog, we will delve into the features, applications, and advantages of this remarkable wire.

Understanding 200°C Polyimide Rectangular Aluminum Enamelled Wire:

The 200°C polyimide rectangular aluminum enamelled wire is a type of magnet wire, also known as winding wire, that is primarily used in the construction of electrical motors, transformers, and various other electrical equipment. It is composed of a rectangular-shaped aluminum conductor, which provides excellent conductivity, and a polyimide enamel insulation that withstands temperatures up to 200°C.

Features and Benefits:

High Temperature Resistance: One of the most notable features of the 200°C polyimide rectangular aluminum enamelled wire is its exceptional resistance to high temperatures. With a maximum operating temperature of 200°C, it can endure the demanding conditions typically encountered in electrical appliances, ensuring optimal performance and reliability.

Excellent Thermal Conductivity: The aluminum conductor of this wire offers excellent thermal conductivity. This feature allows for efficient heat dissipation, which is particularly crucial in high-power electrical applications. The wire effectively minimizes the risk of overheating and helps maintain the longevity of electrical equipment.

Superior Electrical Conductivity: Aluminum is known for its excellent electrical conductivity. The rectangular shape of the conductor in this wire further enhances its conductivity, resulting in low resistive losses during the transmission of electrical current. This attribute translates into improved energy efficiency and reduced power consumption.

Lightweight and Space-Saving: Compared to other traditional copper-based wires, the aluminum conductor in this wire is significantly lighter, making it ideal for applications that require weight reduction. Moreover, the rectangular shape of the conductor allows for space-saving installation, enabling more compact designs of electrical equipment.

Applications:

The 200°C polyimide rectangular aluminum enamelled wire finds applications in various industries, including:

Electrical Motors: It is widely used in the construction of high-performance motors, such as those used in industrial machinery, automotive applications, and appliances. The wire’s ability to withstand high temperatures and its excellent electrical conductivity make it an ideal choice for motor windings.

Transformers: This wire is well-suited for transformer windings due to its high temperature resistance and exceptional electrical properties. Transformers that operate in demanding environments, such as power distribution networks, can benefit from the superior thermal stability and efficiency of this wire.

Electric Vehicles: As the demand for electric vehicles continues to rise, the need for efficient and reliable motor windings becomes crucial. The 200°C polyimide rectangular aluminum enamelled wire is finding applications in the construction of electric vehicle motors, where its high temperature resistance and lightweight properties are highly advantageous.

Aerospace and Defense: The wire’s ability to withstand high temperatures, coupled with its lightweight construction, makes it suitable for aerospace and defense applications. It can be found in aerospace components, such as actuators, servos, and other critical electrical systems.

Conclusion:

The 200°C polyimide rectangular aluminum enamelled wire represents a remarkable advancement in the field of electrical engineering. Its ability to withstand high temperatures, excellent electrical and thermal conductivity, and lightweight design make it an ideal choice for various applications. As technology continues to evolve, this innovative wire opens up new possibilities for designing efficient, reliable, and compact electrical equipment across industries.